WHAT IS LASER MICRO WELDING

Laser micro welding, also known as precision welding, is a specialized technique designed for joining small components using pulsed laser light. This method offers unparalleled precision and minimal heat input, making it ideal for applications where traditional welding methods fall short.

PROCESS OVERVIEW

Laser micro welding uses concentrated light energy to precisely heat the desired weld area, generating much less heat compared to traditional welding methods. The process involves rapid melting and re-solidification of the target material within milliseconds, resulting in a precise fusion of metals on a miniature scale.

ADVANTAGES OF LASER MICRO WELDING

Precision: Allows for pinpoint accuracy, which is crucial for welding small parts.

No Distortion: Minimal heat input reduces the risk of distortion or warping.

No Filler Material Needed: Often, there is no need for additional filler material such as wire.

Electrically Safe: Has no impact on electrically-sensitive components.

WELDING MODES

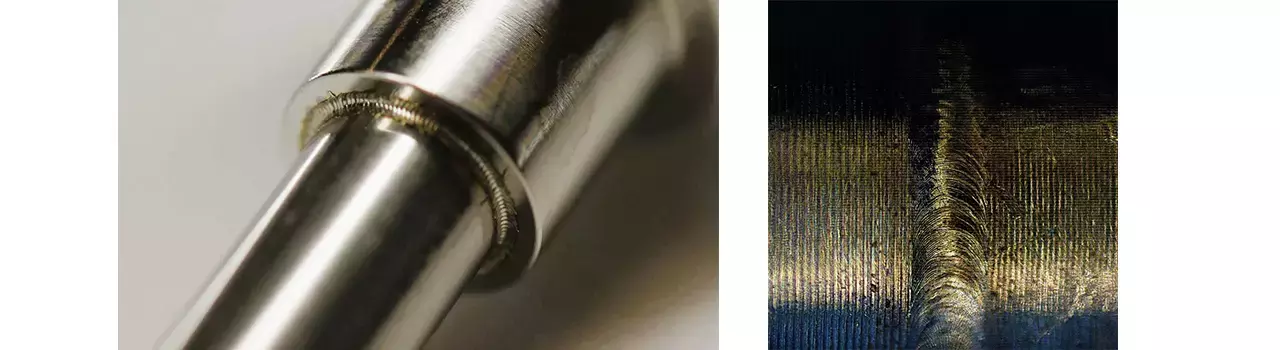

Spot Welding

Overlapping Spot Welding

Medical Industry | Electronics Industry | Automotive Industry |

|

|

|

WHY CHOOSE OPTEK SYSTEMS?

At OpTek Systems, we leverage the latest in laser micro welding technology to deliver precise and reliable welding solutions for various industries. Our expertise ensures that you receive high-quality welds with minimal heat input and distortion, making us the preferred choice for intricate and sensitive welding tasks.

Contact us today to learn more about how our laser micro welding services can benefit your project.