Offering a broad precision processing capability, laser micromachining delivers solutions to a range of aerospace requirements.

Modern aircraft incorporate a range of complex systems and sub-systems in order to deliver the fast, comfortable, efficient, and safe service that we all desire. From avionics to propulsion and hydraulics to inflight entertainment, laser processing is a key technology in aircraft manufacture.

Laser machining is applied in the manufacture of key components needing accurate micron-scale features, while the same processes can be used to create calibration standards, with simulated defects, used in the inspection of performance-critical parts. Lasers are used in the patterning of a transparent or inconspicuous conducting layer on screens, displays and windows and are also key in the production of next-generation optical fiber-based sensors that can be used to monitor performance critical factors like fuel levels and internal engine temperatures. Applications that we’ve been involved in include:

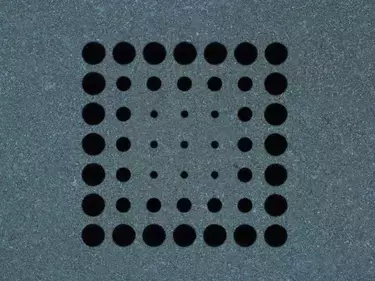

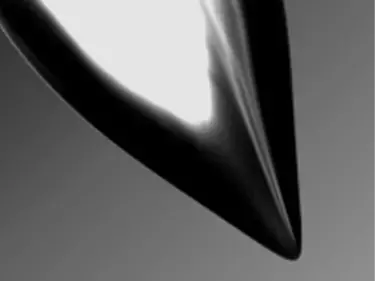

- Development of micro-hole drilling for last chance fluid filters as an alternative to the typical mesh type construction

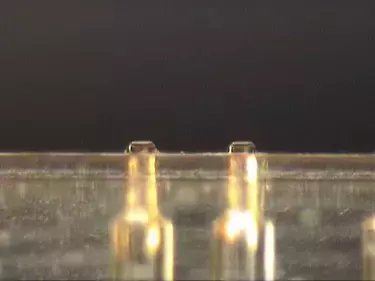

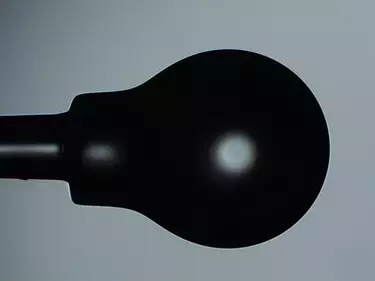

- Development of compact optical fiber termination tools that are compatible with onboard deployment for a rapid, high quality of optical fiber connectors

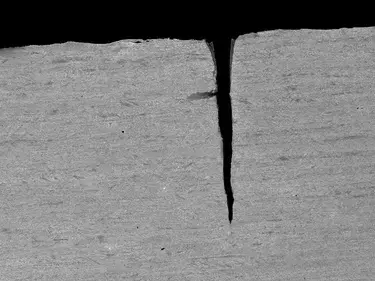

- Laser processing of simulated defects (cracks, pits, and pinholes) to enhance the calibration of defect detection in aircraft structures and components

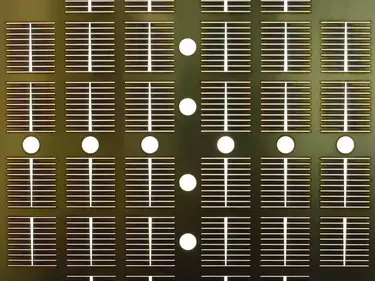

- Laser patterning of thin-film TCO and other coatings for screen demisting and touch-sensitive displays

- Development of portable servicing tools for the inspection and repair of turbine components

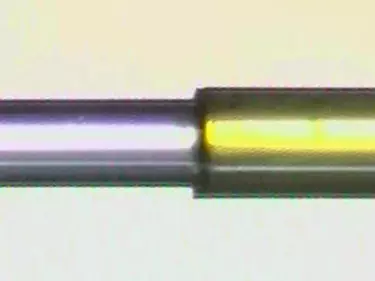

- Laser processing (cutting and fusing) of optical fiber in the production of optical fiber-based sensors for monitoring in high-temperature environments and non-electrical fuel level measurements

- Surface modification (holes and textures) on aerodynamic surfaces in metals and composite materials

We work closely with our customers and partners in the industry to provide advanced technical solutions to key engineering challenges.

Need our help? Fill out our form to ask our OpTek experts.