We are adding value and cost savings in the manufacture of consumer goods and products.

The consumer sector produces a bewildering array of goods and products that are distributed around the globe. While laser processing is clearly not applicable to some types and categories of consumer goods, there are areas where our technology is making a significant difference.

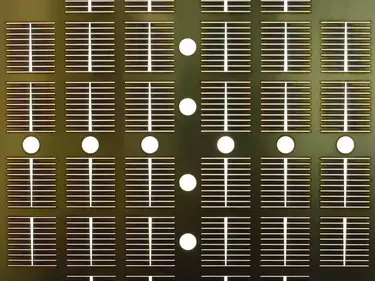

Of course, there are areas where laser micromachining is more obviously applicable like electronic goods. Laser processing is employed in the manufacture of components like capacitors, circuit boards, in touch-sensitive screens and displays, and a range of other areas where ultra-fine precision feature are needed. Laser micromachining is also an enabling technology in some aspect of plastic, printed and flexible electronics, providing critical processes in the creation, programming, and singulation of polymer logic die.

Lasers are also deployed in a range of applications, from product packaging to aerosol nozzle manufacture, helping to provide functionality, improve performance, reduce inventory, and in some cases, enhancing security. Just a few areas where we add value in the consumer sector:

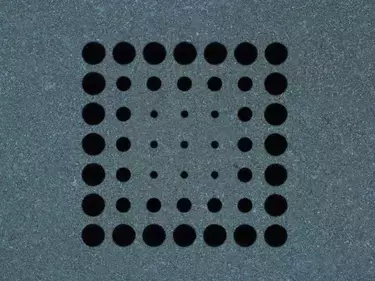

- The development of high-speed laser drilling and inspection of aerosol valves, allowing just in time processing of customer orders from bulk, generic stock. Laser processing delivers a hole size range beyond that which can easily be included in the injection mold. 100% inspection provides confidence that large batches are acceptable for use in downstream assembly processes.

- We can modify the properties of materials like bi-axial polypropylene to create controlled lines, shapes, or regions of material that will separate or open under the appropriate pressure (e.g., for tear strips or pressure relies on packaging).

- We provide manufacturing tools for laser processing of flexible electronics, providing die singulation and release from the carrier substrate, and for hard coding device memory.

- OpTek machines are in routine production around the world, processing optical fiber terminations in consumer cable for applications like optical HDMI.

- OpTek drills millions of small holes every year for electrochemical sensors that are deployed in a domestic and industrial setting.

The highly versatile nature of laser micromachining makes it applicable to a wide range of applications where precision and reproducibility are required in high volume manufacturing.

Need our help? Fill out our form to ask our OpTek experts.