We are providing the capabilities for advanced materials processing in the most challenging of environments.

Since human endeavor put the very first man-made object into space, new technology and manufacturing techniques have been at the forefront of our efforts to explore and operate in the environments outside our planet’s atmosphere.

From the outset, space vehicles must be designed with the best possible strength to weight characteristics and, once launched, the systems on board must operate in the absence (or significantly reduced) of atmosphere and gravity, creating a unique set of challenges for everything from power generation and communications to propulsion.

OpTek’s advanced laser processing capabilities provide the basis for a range of unique and highly specialized techniques to support the production of components and systems destined for space.

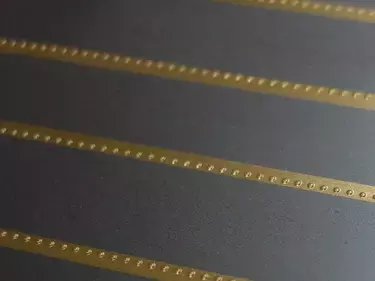

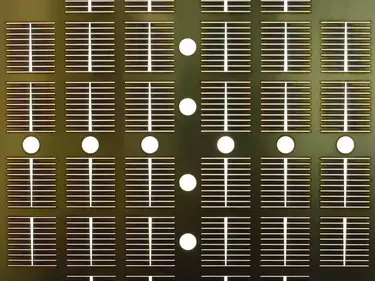

• Processing of thin film, ultra-light photovoltaic cells

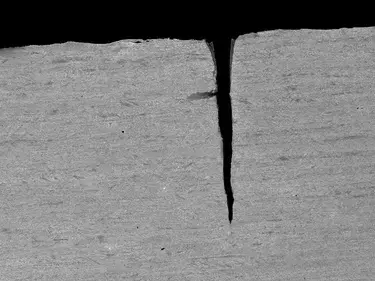

• Laser cutting of ultra-light protective films and materials

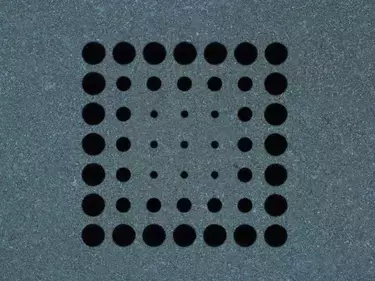

• Laser micro-hole drilling of key components for positioning and propulsion systems

• Patterning of specialized antennae

• Supporting the production of sensors for testing and mission-critical applications

HERMETIC FEEDTHRU ASSEMBLIES (HFA)

Ensuring Hermeticity in Extreme Conditions

At OpTek Systems, our Hermetic Feedthru Assemblies (HFA) are meticulously designed to provide an airtight seal, ensuring a helium leak rate as low as 10^-8 ATM cc/sec. The choice of materials for these assemblies, which includes metallic solders, composites, and glass frits, is tailored to the specific environmental temperatures of your application. Our proprietary materials are capable of maintaining this exceptional hermeticity even at temperatures as high as 700°C, making them ideal for a wide range of demanding environments.

Space and Low-Orbit Applications

For space and low-orbit applications, minimizing outgassing is critical. Our materials are specifically selected and tested to meet these stringent requirements, ensuring that they are suitable for the most sensitive applications. This makes OpTek Systems' HFAs a reliable choice for aerospace and other high-tech industries.

Addressing Thermal Expansion: Minimizing "Pistoning"

Thermal expansion and contraction can cause a phenomenon known as "pistoning," where the fiber moves due to a mismatch in the coefficients of thermal expansion (CTE) of the materials used. At OpTek Systems, we have developed materials that significantly reduce pistoning, ensuring stable performance across a wide temperature range. This stability is crucial for maintaining the integrity and performance of the feedthru assemblies in varying thermal conditions.

Advanced Materials for Superior Performance

In our commitment to providing the highest quality products, we utilize advanced, temperature-resistant furcation materials such as PEEK (polyether ether ketone) in our space applications. PEEK is known for its excellent thermal stability, mechanical properties, and resistance to harsh environments, making it an ideal choice for ensuring the durability and reliability of our HFAs in space.

Why Choose OpTek Systems?

OpTek Systems is dedicated to delivering innovative solutions that meet the rigorous demands of modern applications. Our Hermetic Feedthru Assemblies are designed with precision and care, using advanced materials and cutting-edge technology to ensure superior performance, reliability, and longevity.

Explore our range of HFAs and discover how OpTek Systems can meet your specific needs with our high-quality, hermetically sealed solutions. Contact us today to learn more about our products and how we can assist you in achieving your goals.

Need our help? Fill out our form to ask our OpTek experts.