What makes OpTek special?

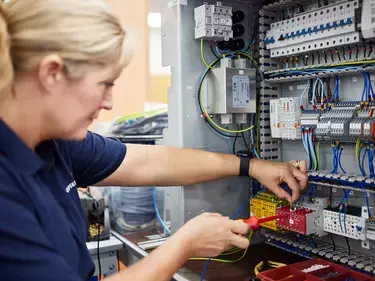

- We are a complete machine build house – we have a complete team of engineers (mechanical, electrical, software and laser engineers) and automation experts along with a build team and a service and support team

- We offer a complete end-to-end, in-house machine build, design, and automation capability

- We are laser neutral, which enables us to select the best solution for any application

- Project management for large and complex projects

Material Processing

On top of the core laser processes we offer for laser micromachining and materials processing, OpTek also provide a range of value-add services to support your project from prototype level through to full-scale production and beyond. This helps to shorten the customer supply chain, decrease lead time, and reduce the risks associated with using multiple vendors.

Here are just a few examples of what we can do:

• Integrating machined components into Sub-assemblies

• Plating

• Sourcing of materials

• Component inspection and quality control, ISO9001:2015

To discuss your specific requirements, please get in touch with OpTek’s laser processing experts.

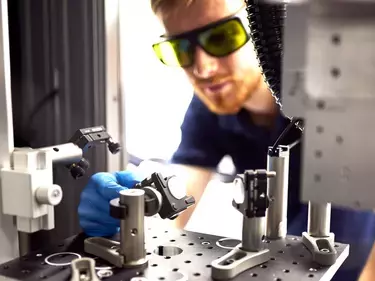

Optical Processing

In addition to the optical fiber processes and equipment available from OpTek, either as a subcontract service, or as fully developed pieces of equipment to be installed at your facility, we also provide a range of value-add services to ensure you are getting the maximum possible value for your project.

Our one-stop-shop for turnkey assemblies provides features for connectorization, metallization, and Fiber Bragg Gratings (FBG’s). We also offer soldering capabilities for the creation of Hermetic Fiber Assemblies and Lensed Fiber Assemblies. Our services and capabilities are well suited for applications and components that need to operate in harsh environments (up to 700°C).