Manufacturing is undergoing a quiet revolution. As components become smaller, lighter, and more complex, traditional machining techniques often struggle to keep up. Engineers in fields as diverse as aerospace, medical devices, semiconductors, and industrial automation are increasingly looking for solutions that can deliver microscopic precision while maintaining repeatability and efficiency at scale. Laser milling has emerged as one of the most effective answers to this challenge.

At its core, laser milling is about sculpting material with light. Instead of relying on cutting tools that wear down or chemical processes that require environmental & safety controls, a laser beam removes material with pinpoint control, layer by layer. This process makes it possible to create cavities, channels, textures, and three-dimensional shapes in a wide range of materials with accuracy that would be almost impossible to achieve by other means.

OpTek Systems has been at the forefront of developing and applying laser milling technologies. By combining decades of expertise in laser micromachining with advanced automation platforms and integrated inspection systems, OpTek helps manufacturers transform designs into production-ready realities.

What is laser milling?

Laser milling is a subtractive manufacturing process that uses the controlled energy of a laser to vaporize or ablate material from a solid surface. Unlike cutting or drilling, that produce a through-feature milling is akin to slicing as a way to create blind features with three-dimensional geometry. The technique is particularly well-suited to 2.5D structures, features such as pockets, shallow cavities, tapered walls, or complex surface contours that require depth control but do not extend through the part.

The key distinction between laser milling and mechanical milling is the absence of physical contact. Traditional milling uses a rotating tool that physically cuts into the workpiece, which introduces forces, vibration, and wear. Laser milling replaces the tool with light, which means no cutting forces, no tool wear, and no limitations imposed by tool geometry. This opens new design possibilities, especially for delicate or hard-to-machine materials.

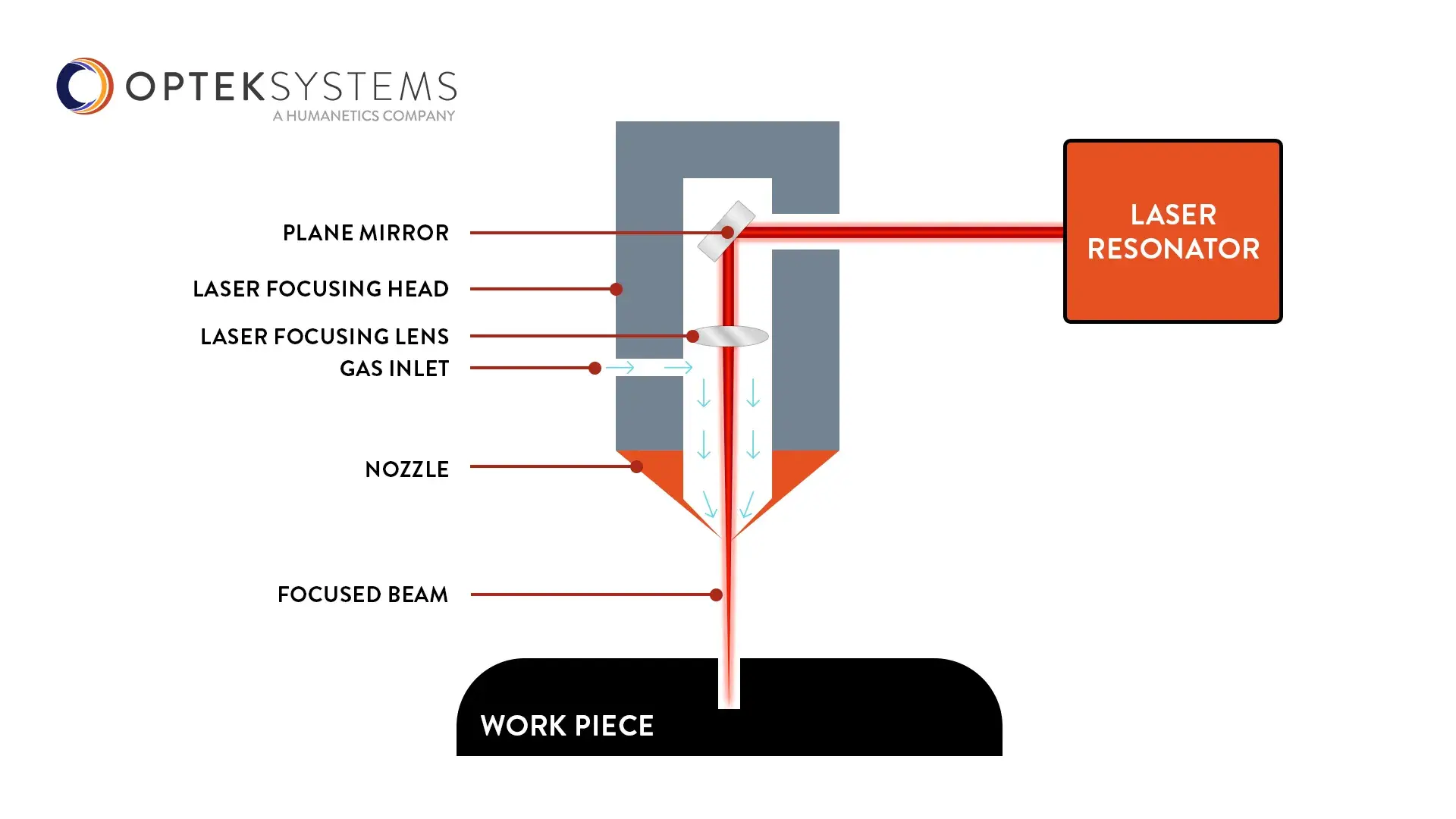

How Laser Milling Works

The effectiveness of laser milling comes from precise control of laser-material interaction. When a focused laser pulse strikes a surface, the material absorbs the energy and vaporizes in a controlled manner. By carefully adjusting the parameters of the laser system, such as pulse energy, pulse duration, wavelength, and repetition rate, engineers can control not only how much material is removed with each pass, but also the quality of the resulting surface.

Excimer UV lasers as well as ultrashort pulsed lasers, are the preferred laser choice for milling applications. UV excimer lasers use mask ablation to ablate large areas and the typical higher absorption of short wavelengths. Ultrashort pulses delivery energy on a timescale that shorter than the conduction time into the surrounding material. The result is a process with minimal thermal effects: no significant heat-affected zone, no micro-cracking, and very little recast material around the edges. Furthermore, the short pulse lasers can increase absorption through non-linear processes, allowing milling of transparent materials.

Equally important is the motion control system. A galvo scanner, for instance, can sweep the laser beam across the surface at high speed, while precision linear stages allow for accurate positioning of the workpiece. The combination ensures that toolpaths can be executed with repeatability measured in microns. Many systems also integrate real-time monitoring, so that the depth of a cavity or the quality of a surface finish can be checked during the process rather than after the fact.

Laser Milling Materials and Applications

One of the reasons laser milling is gaining popularity is its ability to handle a wide range of materials with equal effectiveness. Metals such as stainless steel, aluminium, copper, and titanium can all be milled with high accuracy. Ceramics and semiconductors, including alumina, silicon, and sapphire, are also excellent candidates, as the non-contact nature of the process prevents cracking or breakage. Polymers and composites benefit as well, particularly in industries where lightweight materials must be processed with extreme care.

Applications for laser milling are equally diverse. In medical device manufacturing, for example, laser milling is used to create microfluidic channels in glass or polymer substrates for diagnostic devices. In the semiconductor sector, cavities and recesses can be milled into ceramics and silicon to enable advanced packaging solutions. Aerospace engineers rely on the process to texture surfaces for better adhesion or to create shallow cavities in high-strength alloys. Even in industrial engineering, laser milling is applied to prepare surfaces for bonding, to remove coatings selectively, or to produce intricate features that conventional tooling cannot achieve.

Laser Milling Benefits Over Conventional Techniques

When engineers evaluate manufacturing technologies, they typically consider precision, repeatability, cost, and throughput. Laser milling offers a unique balance across these factors.

First, it provides unmatched precision. Because the laser beam can be controlled digitally and focused to a spot size as small as a few microns, it is possible to achieve feature resolutions and tolerances that mechanical processes simply cannot deliver. Second, the absence of physical contact means there are no cutting forces. This makes it possible to machine thin, fragile, or brittle parts without the risk of distortion or breakage. Third, because there is no tool wear, the process remains stable and repeatable over long production runs.

As throughput requirements scale, automation and multi-beam strategies can increase productivity without compromising quality.

Laser Milling Engineering Considerations

Despite its many advantages, laser milling does come with considerations that engineers must account for in their designs and production strategies. Throughput is often the most significant factor. While the removal rate of laser milling has improved substantially with the advent of high-power ultrafast lasers and burst-mode processing, it is slower than mechanical methods for bulk material removal especially in metals. For this reason, laser milling is often applied where precision is more critical than bulk throughput.

Surface finish is another variable. Depending on the laser parameters and scan strategy, a laser milled surface may have a higher surface roughness. The technology is also restricted to materials that have some degree of light (or heat) absorption. However, optimization of scanning patterns, overlap, and pulse parameters can deliver surface qualities suitable for most applications, and in many cases the as-milled finish is entirely sufficient.

It is also important to consider geometry. Laser milling excels at shallow cavities, tapered surfaces, and fine detail work. Very deep or steep-walled features may require a hybrid approach, combining laser milling with another technique.

Laser Milling Transitioning From Lab to Production

One of the challenges many companies face is moving from proof-of-concept parts to production-ready processes. Milling a single prototype under laboratory conditions is very different from running thousands of parts per month with consistent quality. This is where OpTek Systems provides critical value.

By integrating advanced automation, vision systems, and closed-loop inspection into their platforms, OpTek ensures that the transition from development to production is seamless. We build our custom workstations to manage part handling, loading and alignment through to final inspection, reducing operator dependency and increasing consistency. For industries with strict quality standards, such as aerospace, defense, and medical devices, this integration is vital.

Why OpTek Systems

OpTek Systems has built a reputation as a leader in precision laser micromachining. With deep expertise in laser milling, the company offers not just machines, but complete solutions. From the earliest feasibility studies, through prototyping and pilot runs, to the delivery of turnkey manufacturing systems, OpTek supports customers every step of the way.

The company’s platforms are designed with flexibility in mind. By selecting the most appropriate laser source, beam delivery system, motion control architecture, and inspection technology, OpTek tailors each solution to the specific needs of the application. This ensures that customers are not simply buying equipment, they are investing in a process that is optimized for their products and markets.

OpTek’s global support network further strengthens this value proposition. Customers benefit from training, process optimization, and responsive service wherever they are located, giving them the confidence that production will remain stable as volumes scale.

OpTek Systems Your Partner for Laser Milling Excellence

Laser milling has matured into a powerful and reliable tool for precision manufacturing. By leveraging the unique interaction between light and matter, it allows engineers to design and produce features that were previously impractical or impossible. Its ability to deliver accuracy, repeatability, and flexibility across a wide range of materials makes it an invaluable technique in today’s competitive industries.

For manufacturers looking to harness this technology, choosing the right partner is essential. OpTek Systems combines technical expertise, engineering experience, and a commitment to customer success to deliver not just machines, but complete, production-ready solutions.

If you are exploring new possibilities in laser milling, laser micromachining, or precision manufacturing, now is the time to connect with the experts.