Introduction

Soft and flexible materials such as silicones, elastomers, gels, polymers, and composites have been integral to technological progress across industries for thousands of years. Their inherent compliance, durability, and elastic recovery make them ideal for demanding applications ranging from sealing and gasketing to vibration damping and wearable human-contact components.

However, these same characteristics also make such materials challenging to machine and/or control using traditional fabrication techniques. Optek Systems has developed advanced laser-based machining processes that overcome these challenges and enable highly repeatable, scalable, and precise manufacturing of soft-bodied components. Through partnerships with leaders in medical devices, automotive engineering, as well as the aerospace industry; Optek delivers in-house laser processing services and turnkey laser delivery systems, both backed by process development expertise tailored to complex flexible-material applications.

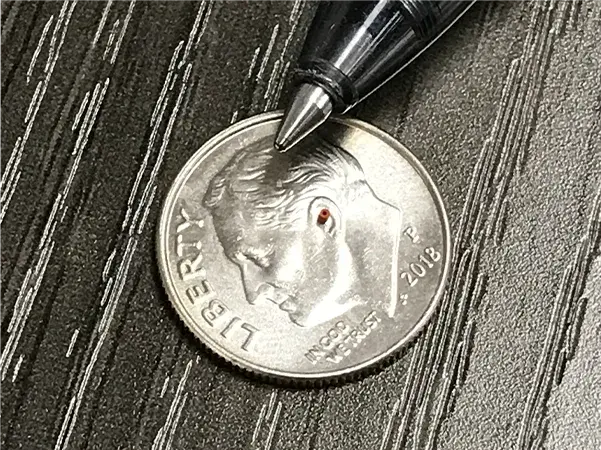

Laser-machined silicone gasket (0.64mm OD – 0.125mm ID) compared size comparison with US dime and ball point pen.

The Role of Laser in Modern Manufacturing

Lasers have become indispensable tools in precision manufacturing due to their abilities regarding:

- Contactless machine and workpiece interaction, eliminating the potential for mechanical deformation during processing

- High spatial and temporal controls, enabling fine-scale feature and tolerance creation

- Flexible beam delivery, compatible with diverse geometries and materials

- Scalability, from prototyping to high-throughput production

By precisely managing the interaction between energized light and soft materials, OpTek Systems can remove, shape or texture material without compromising structural integrity.

Challenges in Machining Soft-Bodied and Flexible Materials

Although soft materials offer desirable mechanical properties, they also introduce unique engineering and manufacturing constraints:

Soft materials typically contain complex interstitial structures (fillers, cross-linked polymers, additives) that affect:

- Dimensional stability

- Thermal sensitivity

- Internal stress distribution

These factors require manufacturing methods capable of controlling deformation and avoiding heat-induced damage.

Traditional machining tools struggle with elastomeric compliance. Soft materials tend to:

- Deflect away from cutting tools

- Tear rather than cutting cleanly

- Generate excessive frictional heat

- Lose tolerances during and after processing

As a result, many geometries are impractical or impossible to achieve with mechanical methods.

Producing soft-bodied components typically requires:

- Custom fixtures to maintain geometry during machining

- Isolated manufacturing cells for each design variant

- Slow cycle times to prevent deformation

These constraints limit scalability, increase cost and reduce responsiveness to design changes.

These constraints limit scalability, increase cost, and reduce responsiveness to design changes.

OpTek Systems Solution: Ultra-Short Pulsed Laser Machining

Optek Systems applications laboratories and integrated production systems utilizes ultra-short pulsed (USP) laser technology combined with galvanometer-based beam steering to cleanly machine soft-bodied materials with exceptional consistency and minimal heat impact; the key capabilities of these systems includes:

USP lasers remove material through photonics energy rather than thermal conduction, resulting in:

- Negligible heat-affected zones (HAZ)

- Sharp, burr-free edges

- No melting, charring or deformation

This is especially critical for medical and aerospace components where surface integrity is paramount.

Galvanometer steering systems enable:

- Sub-micron positional repeatability

- Complex pattern generation

- High-speed, high-throughput machining

Engineers benefit from the ability to produce intricate features that cannot be achieved with mechanical cutting or water jet systems.

OpTek offers end-to-end engineering support, including:

- Material characterization

- Feasibility studies

- Prototype development

- Production process optimization

- Custom system integration

This ensures laser solutions align with both performance requirements and manufacturing constraints.

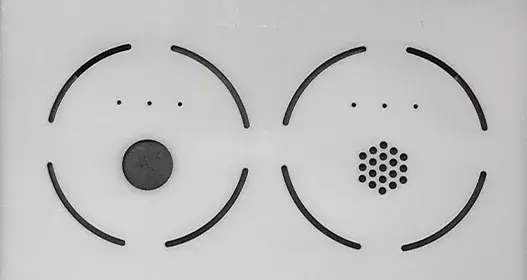

Laser-machined 0.500 um thick PTFE bio-filters with 5mm, 0.6mm, and 0.4mm holes.

Application Example: Laser-Machined Silicone Gaskets

OpTek Systems has successfully demonstrated:

- Micro-scale feature machining

- Consistent dimensional tolerances across production runs

- Clean edge quality without mechanical distortion

- Drastic reductions in scrap and rework

These results substantiate laser machining as a viable and often superior alternative to die cutting, molding modifications and other conventional methods.

Laser-machined silicone gaskets (0.64mm OD – 0.125mm ID) compared with 125 µm fiber-optic strands.

Conclusion

OpTek Systems continues to extend its capabilities in soft-material laser machining, focusing on:

- Higher machining throughput

- Improved positional accuracy

- Broader material compatibility

- Automated and inline production integration

By combining advanced laser hardware with robust process engineering, OpTek Systems provides manufacturers with a scalable, reliable and cost effective pathway to creating soft-bodied components previously considered unmachinable.