Conformal coatings, such as Parylene and multilayer polymer films, are widely used to protect electronic components from environmental factors. However, there are instances when these coatings need to be removed for repairs or modifications.

In this article, we will delve into the efficient removal of conformal coatings from substrates, including Parylene and multilayer polymer films, and highlight how Optek's laser ablation technology enables targeted removal with minimal damage to the exposed layers.

Additionally, we will explore how Optek's technology can facilitate surface modification of the exposed substrate, making it hydrophobic or hydrophilic if required.

What are conformal coatings and why are they used?

Conformal coatings are thin protective layers that are applied to electronic components and assemblies to protect them from environmental factors, such as moisture, dust, chemicals, and temperature fluctuations. These coatings conform to the contours of the components, providing a uniform and continuous protective barrier.

Conformal coatings serve several important purposes in electronic applications:

Moisture Protection: Moisture can cause corrosion, short circuits, and other electrical failures in electronic devices. Conformal coatings act as a barrier, preventing moisture ingress and protecting the sensitive electronic components from damage.

Environmental Protection: Electronic components are often exposed to harsh environments, including dust, dirt, chemicals, and temperature extremes. Conformal coatings provide a protective layer that shields the components from these elements, extending their lifespan and enhancing reliability.

Insulation and Dielectric Strength: Conformal coatings offer electrical insulation properties, preventing current leakage and short circuits. They also enhance the dielectric strength of the components, ensuring that electrical signals are properly transmitted without interference or degradation.

Chemical Resistance: Some conformal coatings exhibit resistance to various chemicals, including solvents, acids, and bases. This chemical resistance protects the components from potential damage caused by exposure to these substances in their operating environment or during maintenance.

Mechanical Protection: Conformal coatings can provide a certain degree of mechanical protection by acting as a barrier against physical abrasion, vibration, and impact. They help safeguard the delicate electronic components from mechanical stresses and potential damage.

UV Protection: Certain conformal coatings offer UV resistance, shielding the components from the harmful effects of ultraviolet radiation. This is particularly important for outdoor or exposed electronic devices that are susceptible to UV-induced degradation.

Anti-Fungal and Anti-Microbial Properties: Some conformal coatings possess anti-fungal and anti-microbial properties, inhibiting the growth of mold, mildew, or bacteria on the coated surfaces. This is particularly valuable in applications where cleanliness and hygiene are crucial, such as medical devices or food processing equipment.

By providing these protective benefits, conformal coatings contribute to the reliability, longevity, and performance of electronic components and assemblies. They are widely used in various industries, including aerospace, automotive, medical devices, telecommunications, consumer electronics, and industrial equipment, to safeguard electronics and ensure their functionality in challenging operating conditions.

Why do conformal coatings need to be removed?

Repair and Rework: During the repair or rework of electronic components or assemblies, it may be necessary to remove the existing conformal coating. This could be due to the need to access and repair specific components, modify circuitry, or replace damaged parts. Removing the coating allows technicians to effectively perform the required repairs or modifications.

Upgrades and Modifications: As technology advances, electronic components often undergo upgrades or modifications to improve their performance, functionality, or compatibility. Removing the existing conformal coating enables the implementation of these changes and ensures proper integration of new components or features.

Testing and Inspection: Conformal coatings can hinder the testing and inspection processes for electronic components. Removing the coating allows for better access to the components, facilitating electrical testing, visual inspection, and quality control checks. This ensures that the components meet the required standards and specifications.

Surface Preparation: In certain cases, the removal of the conformal coating is necessary to prepare the surface for subsequent processes or applications. For example, if a new conformal coating is to be applied, the old coating must be removed to ensure proper adhesion and performance of the new coating. Similarly, if the surface needs to be prepared for soldering or wire bonding, the existing coating must be removed to ensure good electrical connections.

End-of-Life Disposal or Recycling: When electronic components or assemblies reach the end of their useful life, they may need to be disposed of or recycled. Conformal coatings can impede the recycling or recovery of valuable materials from these devices. Removing the coatings allows for efficient separation and processing of the different components and materials during the recycling or disposal process.

Traditional methods for protective coating removal

Alternatives to protective coating removal include traditional methods such as mechanical scraping, sanding, and the use of chemical solvents. While these methods have been employed in the past, they come with several drawbacks when compared to laser ablation technology.

Mechanical Scraping and Sanding: These methods involve physically scraping or sanding off the protective coating. However, they can be labour-intensive and time-consuming. Moreover, there is a risk of damaging the underlying substrate or components due to the force applied during scraping or sanding. Delicate or sensitive components may be vulnerable to mechanical stress, leading to potential malfunctions or reduced performance.

Chemical Solvents: Chemical solvents are often used to dissolve or soften the protective coating, allowing it to be wiped or washed away. While solvents can effectively remove some coatings, they can be hazardous to handle and require careful disposal to avoid environmental contamination. Moreover, certain solvents may have limitations in removing specific types of coatings, and their use may pose health and safety risks.

What is the best way to remove conformal coatings?

The removal of conformal coatings from substrates requires precision and care to avoid damage to underlying layers.

Optek's laser ablation technology offers an advanced solution that allows for targeted removal with minimal impact on exposed layers. This technology utilizes laser energy to selectively remove the conformal coating, ensuring that the substrate remains intact while effectively eliminating the protective layer.

Parylene Removal

Parylene is a popular conformal coating known for its excellent chemical resistance and adhesion properties. However, removing Parylene without damaging the substrate can be challenging. Optek's laser ablation technology provides a precise and controlled approach to remove Parylene coatings.

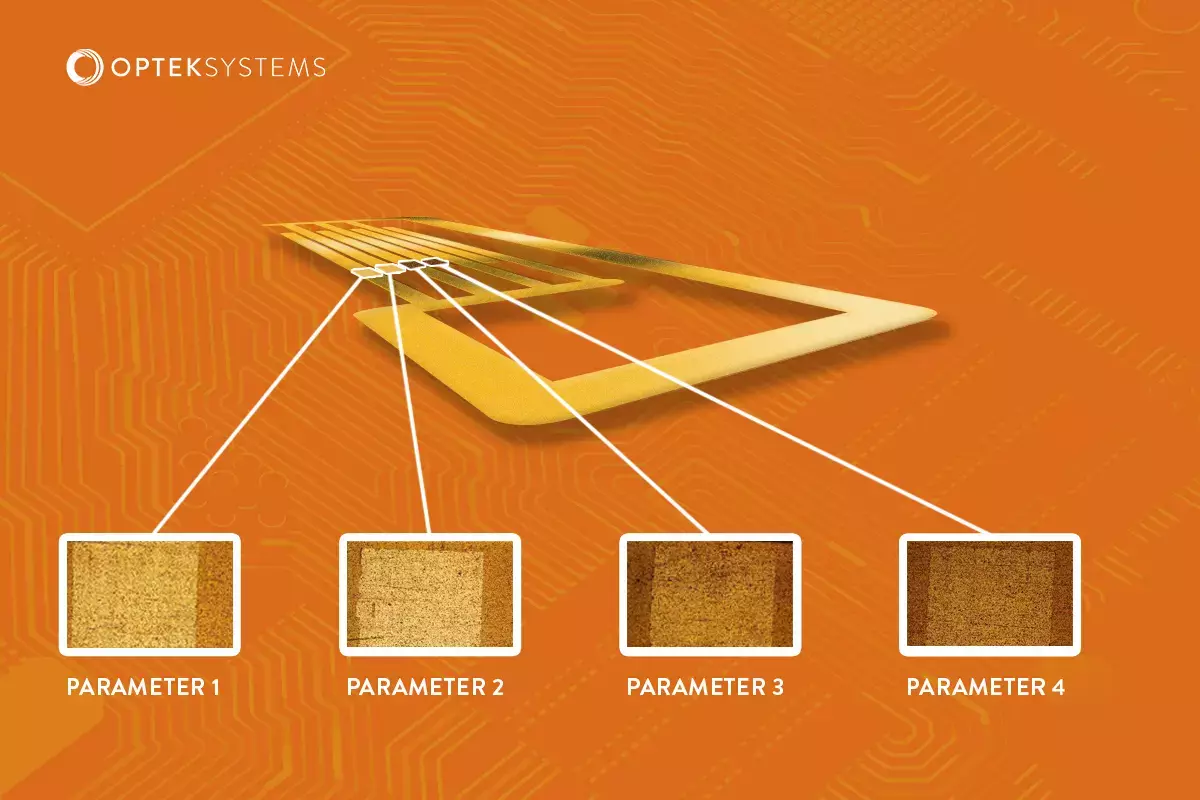

By adjusting the laser's energy parameters, technicians can precisely vaporize the Parylene layer without affecting the underlying substrate, ensuring its integrity remains intact.

Multilayer Polymer Film Removal

Multilayer polymer films are often used as conformal coatings to provide protection and insulation to electronic components. When it becomes necessary to remove these films, Optek's laser ablation technology offers an ideal solution. The laser energy is absorbed by the polymer film, causing it to vaporize and be removed selectively. This targeted approach ensures that the underlying layers remain undamaged, enabling efficient removal without compromising the substrate's integrity.

Targeted Removal with Minimal Damage

Optek's laser ablation technology enables precise and targeted removal of conformal coatings, ensuring minimal damage to the exposed layers. Unlike traditional methods that may involve mechanical scraping or harsh chemicals, laser ablation eliminates the risk of physical contact or chemical reactions that could harm the substrate. By precisely controlling the laser's energy and beam, Optek's technology allows for the removal of coatings with exceptional accuracy and minimal disruption to the substrate's structure.

Why is laser ablation the best method for protective coating removal?

Precision and Selectivity

Laser ablation allows for precise and selective removal of the protective coating layer. By adjusting the laser parameters, such as energy density and pulse duration, technicians can target and vaporize the coating while leaving the underlying layers and components untouched. This level of precision is crucial for preserving the integrity and functionality of the substrate.

Non-Contact and Non-Destructive

Laser ablation is a non-contact process, eliminating the risk of physical damage to the substrate or components. Unlike mechanical methods that involve scraping or sanding, laser ablation does not subject the substrate to mechanical stress or abrasion. This non-destructive nature ensures that the substrate remains intact and reduces the potential for performance degradation.

Chemical Inertness

Laser ablation does not require the use of chemical solvents, eliminating the associated safety concerns and environmental impact. Chemical inertness is particularly important when removing coatings like Parylene, which demonstrate high resistance to solvents. Laser ablation bypasses the need for chemical interactions, providing a safe and efficient alternative. Some materials however emit hazardous decomposition products when ablated, therefore we recommend an MDSD to evaluate before processing.

Flexibility and Customization

Laser ablation technology offers flexibility in terms of adjusting laser parameters to suit different coating materials and thicknesses. Technicians can tailor the process to accommodate specific requirements, ensuring optimal coating removal. Additionally, laser ablation can be automated, enabling high-speed and consistent removal in industrial settings.

Surface Modification Capabilities

In addition to coating removal, lasers can modify the surface properties of the exposed substrate. Laser processing can create desired surface textures, patterns, or even alter the surface's wettability, making it hydrophobic or hydrophilic. This capability opens up possibilities for enhancing the substrate's functionality or improving its compatibility with subsequent manufacturing processes.

Parylene and Multilayer Polymer Film Removal in Summary

Optek's laser ablation technology provides an efficient and precise solution for removing conformal coatings, including Parylene and multilayer polymer films, from substrates. With the ability to perform targeted removal while minimizing damage to exposed layers, Optek's technology ensures the integrity of the underlying substrate remains intact.

Furthermore, the surface modification capabilities enable the customization of substrate properties, facilitating the creation of hydrophobic or hydrophilic surfaces when necessary.

By leveraging Optek's advanced laser ablation technology, industries can achieve efficient coating removal and tailor substrate surfaces to meet specific requirements, opening up new possibilities in electronic component manufacturing and beyond.