Introduction

In advanced manufacturing, hardened surface materials such as molybdenum, titanium, and ceramics are critical for applications requiring exceptional wear resistance, thermal stability, and structural integrity. These materials are widely used in aerospace, medical devices, semiconductor manufacturing, and energy systems, where precise geometries at the microscale are essential to performance.

However, the same properties that make these materials ideal for extreme environments also make them difficult to machine. Traditional milling and EDM processes often struggle to achieve tight dimensional tolerances, smooth surface finishes, and micro-scale repeatability without causing surface damage or part deformation.

To meet the growing demand for precision micro machining in hard materials, OpTek Systems has developed an ultra-short pulsed laser micro milling process capable of delivering micron-level accuracy and minimal thermal impact. This technology opens new possibilities for complex designs and functional surfaces.

Problem: Challenges of Machining Hard Surface Materials

Machining hardened materials presents a double-edged sword in manufacturing. The enhanced surface hardness that provides wear resistance and performance stability also introduces major obstacles to processing:

- Resistance to mechanical cutting: Conventional tools wear quickly, increasing cost and reducing accuracy.

- Risk of embrittlement and cracking: Mechanical or thermal stresses can cause microfractures in the surface layer.

- Deformation or failure risk: Excessive force or heat can distort fine features or lead to premature component failure.

Even advanced subtractive techniques such as diamond turning or micro-EDM can induce surface damage, residual stress, or loss of dimensional control, especially when feature sizes fall below 100 µm.

These limitations have long restricted the use of hardened materials in applications requiring intricate geometries.

Solution: Ultra-Short Pulsed Laser Micro Milling

OpTek Systems addresses these challenges with a non-contact, galvo-controlled laser ablation process optimized for micro-scale precision machining of hard materials.

By using ultra-short pulsed lasers operating at 315 nm, 515 nm, and 1064 nm with average powers between 3 and 20 W, OpTek’s process enables:

- Micron-by-micron depth control for exact feature definition.

- Minimal heat-affected zones (HAZ) to preserve surface integrity.

- Surface roughness averages under 400 nanometers, even on highly polished materials.

- Consistent repeatability across batches and complex geometries.

This approach combines galvanometer-based beam steering with precisely tuned pulse durations to ablate material efficiently, achieving surface conditioning and patterning that were previously unfeasible with mechanical methods.

The result is high-speed, high-precision micro-machining of materials that were once considered unmachinable.

Case Studies: Technology in Action

Molybdenum Bearing Shaft

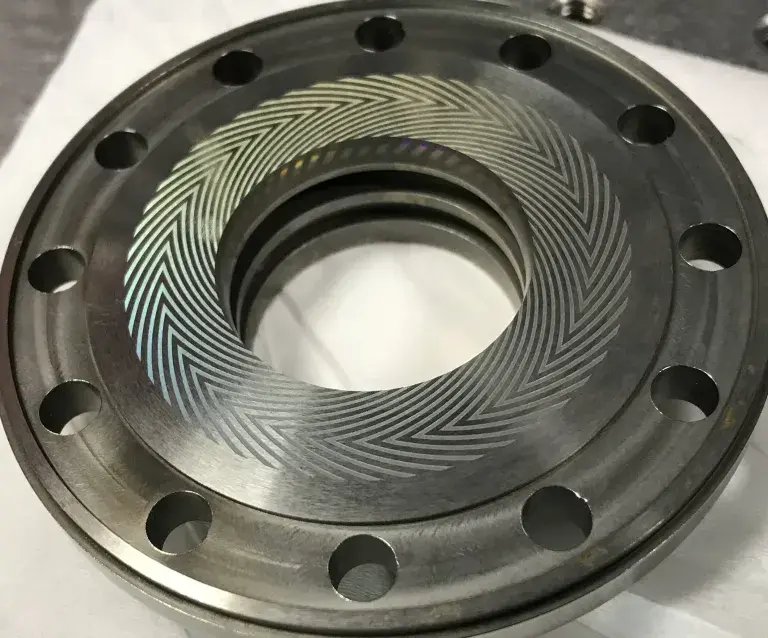

Using galvanometer-based laser ablation, OpTek successfully machined chevron patterns along the circumferential surface of polished molybdenum shafts.These features are designed forfluid flow regulation in gas bearings.

- Groove depth: 20 µm

- Dimensional tolerance: ±1 µm

- Surface roughness: <400 nm Ra

This level of precision allows micro-feature sets to be integrated directly into functional bearing surfaces, improving lubrication dynamics and component lifespan without post-processing.

Figure 1: Molybdenum cylinder with chevron pattern grooves laser-machined along the circumferential surface.

Titanium-Plated Ceramic Components

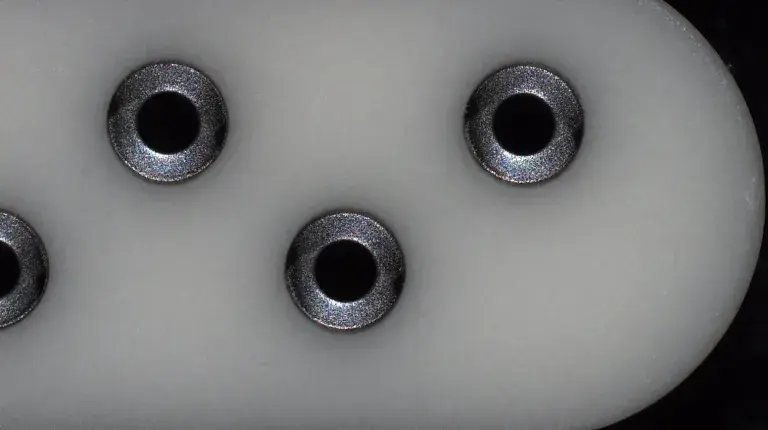

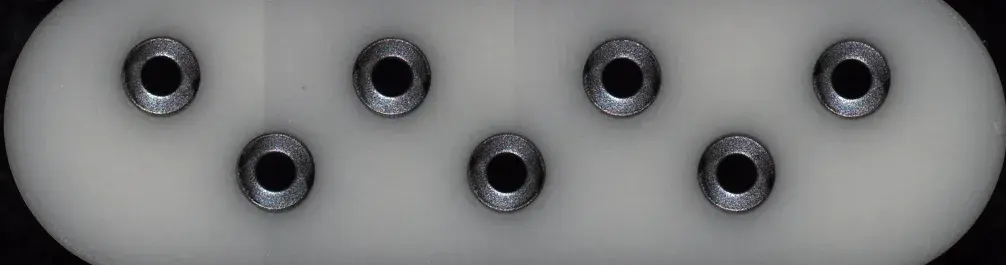

In another application, OpTek employed selective micromilling to remove titanium coatings from ceramic substrates without compromising the base material. The process enabled targeted feature definition in nearly finished parts while maintaining design-critical dimensions and avoiding thermal distortion.

Figure 2: Selectively machined titanium plated ceramic plate.

Broader Applications

The same technology has been applied across industries for:

- Pressurized fluid control components in aerospace and energy sectors.

- Micro-needle fabrication for biomedical applications.

- Precision crystal circuit patterning in semiconductor and photonics assemblies.

Each application leverages the controllable depth, fine resolution, and repeatability of OpTek’s laser-based micro-manufacturing process.

Conclusion

OpTek Systems has developed and refined a micro milling process that enables the precise machining of hard and high-performance materials once considered impractical with conventional techniques.

Through ultra-short pulsed laser machining, engineers can now achieve:

- Higher feature precision

- Minimal surface damage

- Improved throughput and design flexibility

Ongoing development focuses on enhancing processing rates and improving accuracy, reinforcing OpTek’s commitment to continuous innovation in advanced laser micro-manufacturing.

In summary, OpTek’s micromilling technology transforms the challenge of hard material machining into an opportunity, delivering precision, performance, and process reliability at the microscale.