Laser stripping from OpTek Systems provides controllable and reproducible removal of acrylate or polyimide buffers with tight control over the position, location, and fiber-strength.

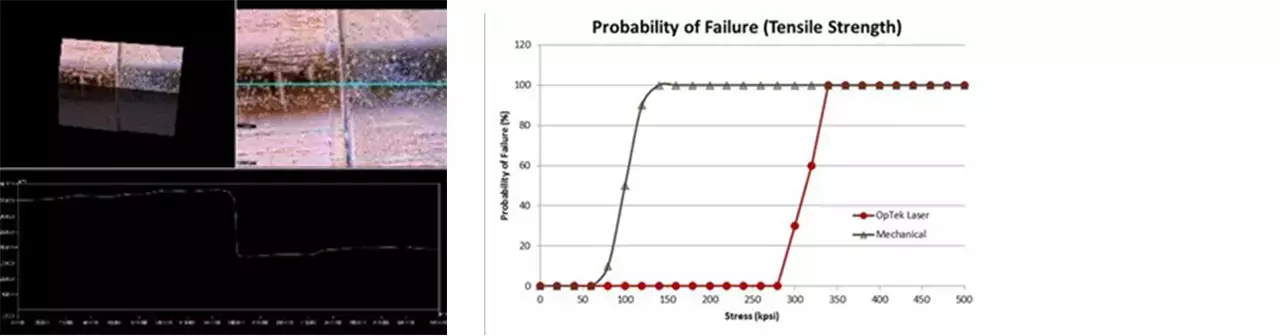

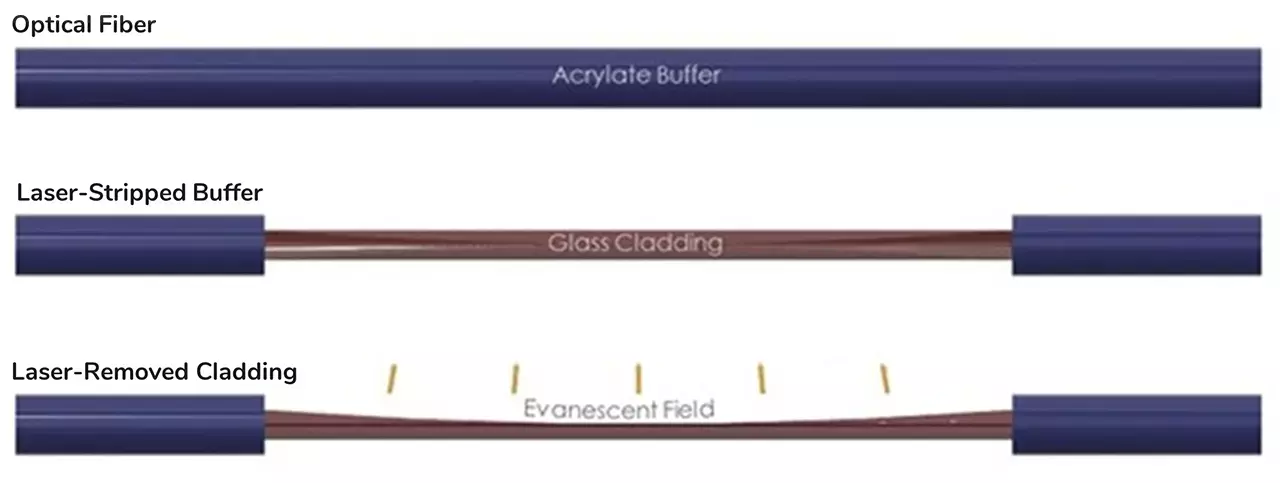

Laser stripping of optical fiber is the fast and accurate way to remove acrylate and polyimide coatings, in order to access the fiber for additional processing, termination, and packaging. As a contact-free alternative to hot air, chemical, and mechanical (blade) stripping, the laser stripping process can be configured for end or window-stripping with precise positioning, dimensional control, and high tensile strength. The elimination of blades and any form of glass abrasions make this an ideal process for ultra-high reliability (UHR) applications. The laser stripped fiber is clean and residue-free and avoids the hazards and controls associated with chemical stripping. The process can be applied to create windows of virtually any length and at any point along with the fiber, making it ideal as a preparatory step for processes such as the writing of Fiber Bragg Gratings (FBG’s).

Laser stripping is a highly flexible and repeatable process that offers selective and precise removal for clad/core ablation with the ability to remove short and long lengths in single or multiple locations, with control over the profile of the strip transition. The process can also be combined with laser cleaving or lensing for efficient processing of fiber tails from a spool. Round and non-round fibers, ribbons, and arrays can be accommodated, covering a wide range of applications, such as chemical and biological sensing, along with those that operate in harsh environments.

Laser Stripping and Ablation

Laser stripping of optical fibers is a contact-free process used for the removal of acrylate, polyimide and other exotic buffers. The process can be configured for end-stripping and window-stripping with precise dimensional control.

The elimination of blades and any form of glass abrasions make this an ideal process for ultra-high reliability (UHR) applications.

Laser Stripping

Laser stripping of optical fiber offers a rapid and precise method for removing acrylate and polyimide coatings, facilitating access to the fiber for subsequent processing, termination, and packaging. Serving as a contactless alternative to conventional hot air, chemical, and mechanical (blade) stripping methods, laser stripping can be tailored for either end or window stripping, ensuring exact positioning, dimensional accuracy, and exceptional tensile strength. By eliminating blades and minimizing the risk of glass abrasions, this technique is particularly well-suited for ultra-high reliability (UHR) applications. The resultant fiber from laser stripping is devoid of residues, providing a clean outcome and sidestepping the safety concerns and stringent controls associated with chemical stripping. Moreover, this process allows for the creation of windows of varying lengths and at any desired location along the fiber, making it an ideal preparatory step for procedures such as Fiber Bragg Gratings (FBGs).

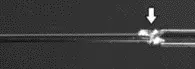

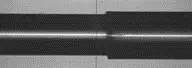

| Mechanical Processing | Glass Abrasions, Irregular Transition |

|  |

| Laser Processing | Non-contact, Sharp Transition |

|  |