Laser Cleaving developed by OpTek Systems has been adopted globally to address the challenges faced in the volume processing of optical fibers.

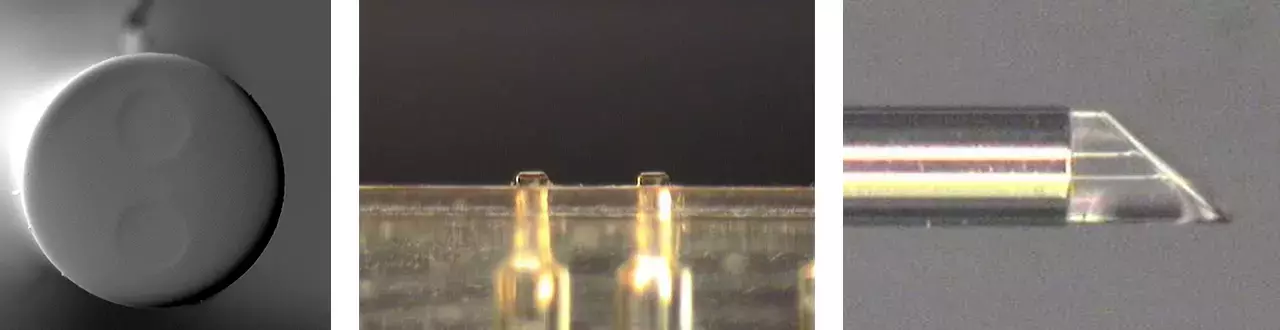

Fiber cleaving uses advanced laser technology to offer a precise and accurate alternative to traditional mechanical methods. This technique enables the termination of optical fibers with exceptional precision, producing flat or angled facets across a wide range of fiber types and waveguides.

Compared to mechanical processes, laser cleaving delivers volume processing with superior optical quality, making it suitable for applications using single fibers, ribbons and arrays.

Particularly well-suited for free-space optical interfaces, laser cleaving ensures optical-grade transmission without the need for additional polishing. Furthermore, it effectively eliminates common issues encountered in mechanical processing, such as core cracks, lips, hackle and misting.

The precision laser cleaving process offers exceptional control over the end face angle, allowing for precise adjustments ranging from 0 to 60 degrees. Moreover, the laser cleave can be accurately positioned in relation to other fiber features, such as metallization or a connector body. This level of precision extends to more intricate end face geometries, enabling the creation of multi-faceted forms and a diverse range of lens geometries. Such flexibility allows for tailored adjustments to the end face geometry, ensuring optimal suitability for each unique application.

OpTek's laser cleaving process, pioneered in the early 21st century, serves as the heart of our expanding portfolio of production equipment and subcontract manufacturing services. Initially developed for broadband optical telecommunications, OpTek's laser cleaving now empowers a wide range of industries, including telecoms, datacoms, fiber lasers, biomedical, and sensing applications. By leveraging its distinctive performance advantages, OpTek's laser cleaving consistently delivers outstanding results in these fields.

For more information, or to discuss your specific laser cleaving or fiber processing requirements, please contact one of OpTek’s representatives.

Laser Lensing / Cleaving - High Coupling Efficiency

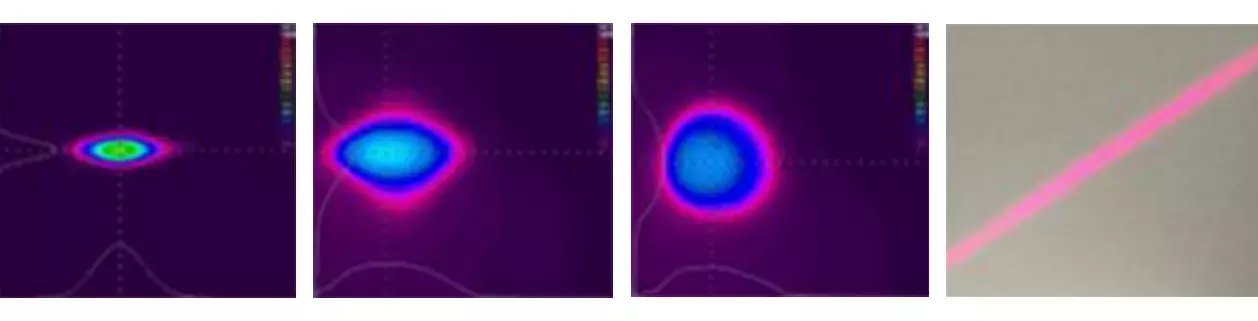

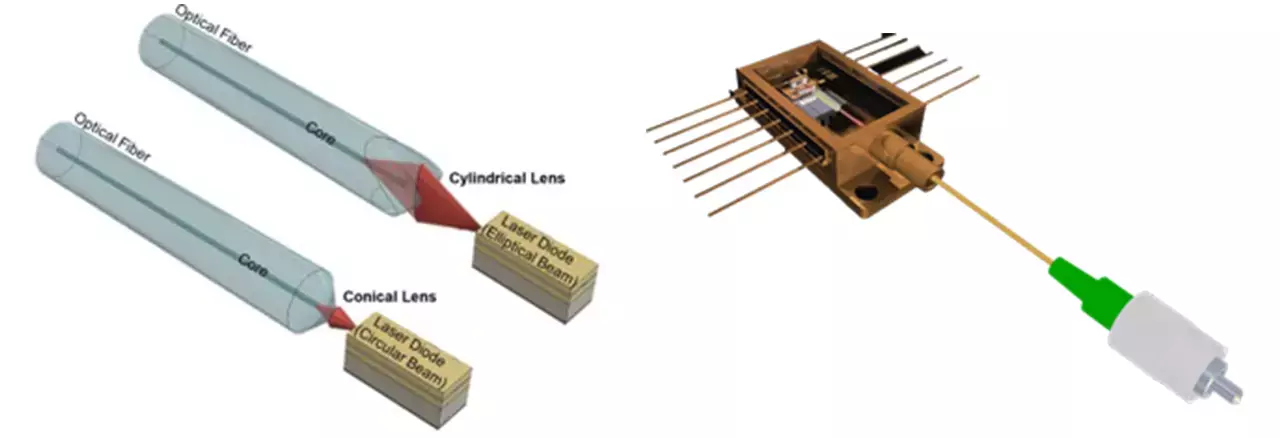

Lensed fibers are often the method of choice for interfacing optical fiber to active devices and waveguides. Lensing technology provides highly efficient coupling while consuming a fraction of the space and costs of bulk optic alternatives. Fiber lenses are typically created to match the emission profiles of the receiving or transmitting device to which they are coupled.

| CONICAL LENS | WEDGE & BICONIC LENS | BALL LENS | FLAT & ANGLE CLEAVES | |

|---|---|---|---|---|

|  |  | ||

| Application | Active & Waveguide Coupling Circular FF (1:1 – 2:1) | Active & Waveguide Coupling Elliptical FF (≥2:1) | Long Working Distance Collimation TIR | TIR Low BR EFPI Sensors Capillaries |

| Included Angle | 50 – 110° (± 5.0°) | 50 – 110° (± 5.0°) | NA | 0 – 60° (± 1.0°) |

| Tip Radius | 3 – 60µm (± 1.0µm) | 3 – 40µm (± 1.0µm) | 100 – 1,200µm (± 1.0µm) | NA |

| Lens Centration | 0.5µm | 0.5µm | 0.5µm | NA |

| PM Alignment | ± 3.0° | ± 3.0° | ± 3.0° | ± 3.0° |

Laser-produced lensed fiber technology offers:

- Increased coupling efficiency;

- Decreased alignment sensitivity

- Customization around focal length, spot size and far-field parameters

- Creation of challenging beam profiles, such as line, radial, TIR and ring emissions

- Increased reliability – Far-field feedback eliminates rework and inspections

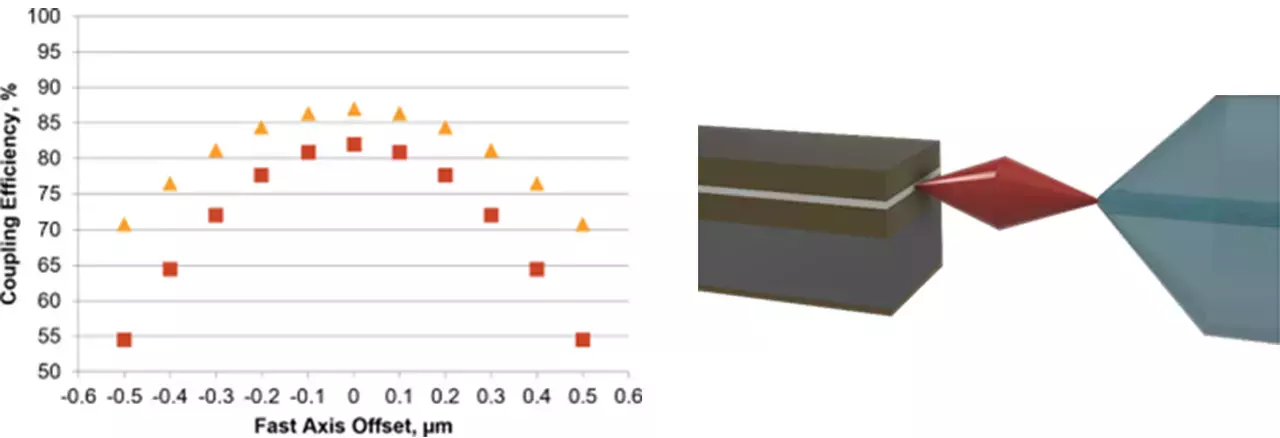

Coupling efficiency and ease of alignment are the two critical criteria when manufacturing laser diodes, fiber optic gyros, or any active device that requires interfacing to an optical fiber.

The graph below depicts coupling efficiencies as a function of offset (lens from diode chip). Laser processed lenses can be maximized around coupling efficiency while preserving offset insensitivities, a highly desired feature during the lockdown and packaging stage of production.