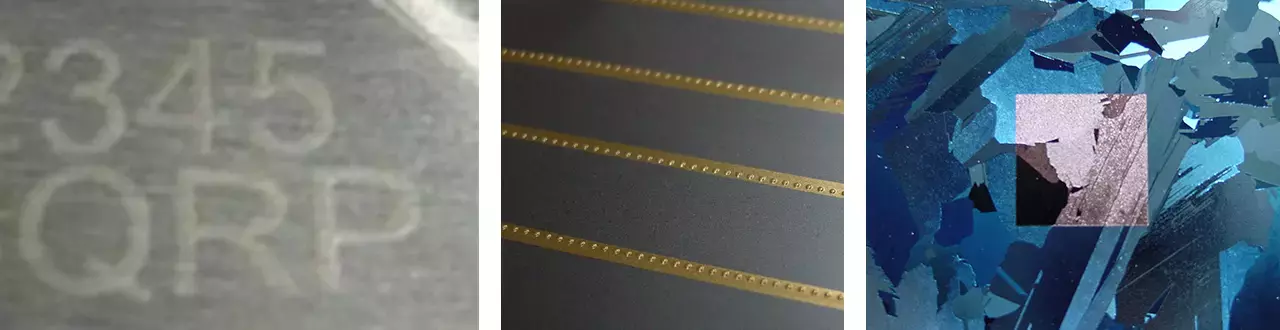

Laser marking is well suited to the creation of fine lines and other blind features and patterns on a wide range of substrates, thin films, and coatings. Laser marking is widely applied across a range of industries for both aesthetic, informative and functional purposes.

Laser marking encompasses a number of terms including micro scribing and thin film scribing and is used to create precisely controlled, fine-scale grooves or write fine lines. Laser energy can be applied to the material in one of two ways, either focused to a small spot and scanned over the surface or imaged through a mask to project the pattern onto the surface. The use of laser marking allows for very accurate writing of fine features both in the surface of a material and by the removal of one or more layers in a multi-layer substrate.

Through the use of precision laser processing, it is possible to selectively target individual layers in thin film devices, such as capacitors and batteries, creating a highly versatile patterning process. The laser process can be used for thin film coating isolation or area ablation by removing one deposited layer from another or from the underlying substrate, which is critical for the processing of isolation scribes in thin film solar cell and capacitor production. Through careful selection of the laser type and process parameters, virtually any material can be scribed, including those that are highly reflective or transparent.

OpTek also specializes in high precision marking for critical industries, such as traceability for medical devices and pharmaceutical applications. We can offer black marking along with techniques for corrosion resistant marking of more challenging requirements and can provide entirely bespoke solutions, meaning that no matter how difficult or unusual your material or component is, we can deliver the processing and equipment you need.