LaserStrip-1500

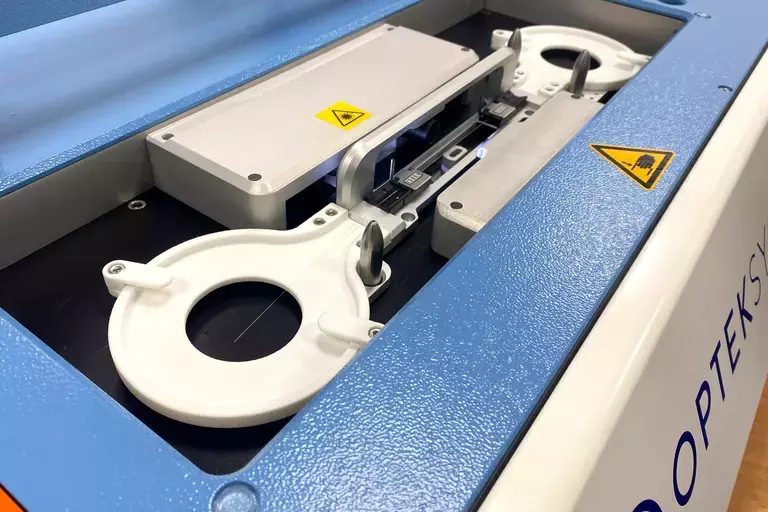

Tabletop fiber processing tools for optical component production. LaserStrip production tools from OpTek Systems are built around the technology that has been relied on in performance critical, volume production of optical fiber components since the mid 1990’s. Engineered to address the production of existing and a new generation of components, in a compact and user friendly platform LaserStrip™ is designed to maximize productivity in manufacturing.

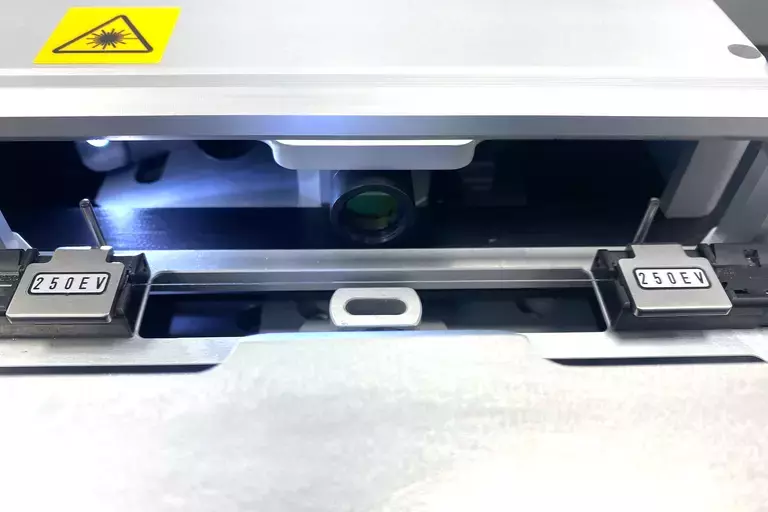

Laser stripping of optical fibers is a contact-free process used for the removal of acrylate buffers. This system is configured for single-fiber window-stripping with strip lengths up to 30mm and precise dimensional control. The elimination of blades and any form of glass abrasions make this an ideal process for ultra-high reliability (UHR) applications.

Specifications

Key Features

- Rapid, non-contact processing

- Accurate and repeatable feature positioning

- Eco-friendly manufacturing (chemical free)

- Improve performance, increase yield, reduce manufacturing costs

- RELIABILITY The elimination of blades and, consequently, glass abrasions make this an ideal process for ultra-high reliability (UHR) applications

- Accurate and repeatable strip length with clean and well-defined shoulder

- High-throughput - processing time is less than 1 minute/fiber including load and unload operations