As global energy demands grow, the battery industry faces increasing pressure to improve efficiency, longevity, and scalability.

Laser micromachining is revolutionising energy storage, generation, and distribution by enabling ultra-precise, high-speed processing of critical battery components. This technology eliminates many limitations of traditional mechanical methods, reducing waste, improving structural integrity, and ensuring tighter production tolerances.

By integrating real-time quality assurance systems and machine learning algorithms, manufacturers can enhance production efficiency, lower defect rates, and maximize throughput. The demand for higher energy density and longer cycle life in next-generation batteries makes laser micromachining an essential solution for improving anode, cathode, and thin-film processing.

This article explores how laser micromachining is transforming battery manufacturing and how OpTek Systems provides industry-leading solutions to achieve scalability, precision, and defect-free production.

TRANSFORMING BATTERY MANUFACTURING

WITH PRECISION LASER TECHNOLOGY

Laser technology plays a critical role in modern battery production, offering unmatched precision, efficiency, and process control. Across various stages of manufacturing, lasers enable high-speed, defect-free processing that enhances performance, longevity, and scalability.

Enabling precise cutting of anode, cathode, and separator materials with micron-level accuracy while minimising material waste.

Selectively removing conductive layers to improve electrical performance and reduce short-circuit risks.

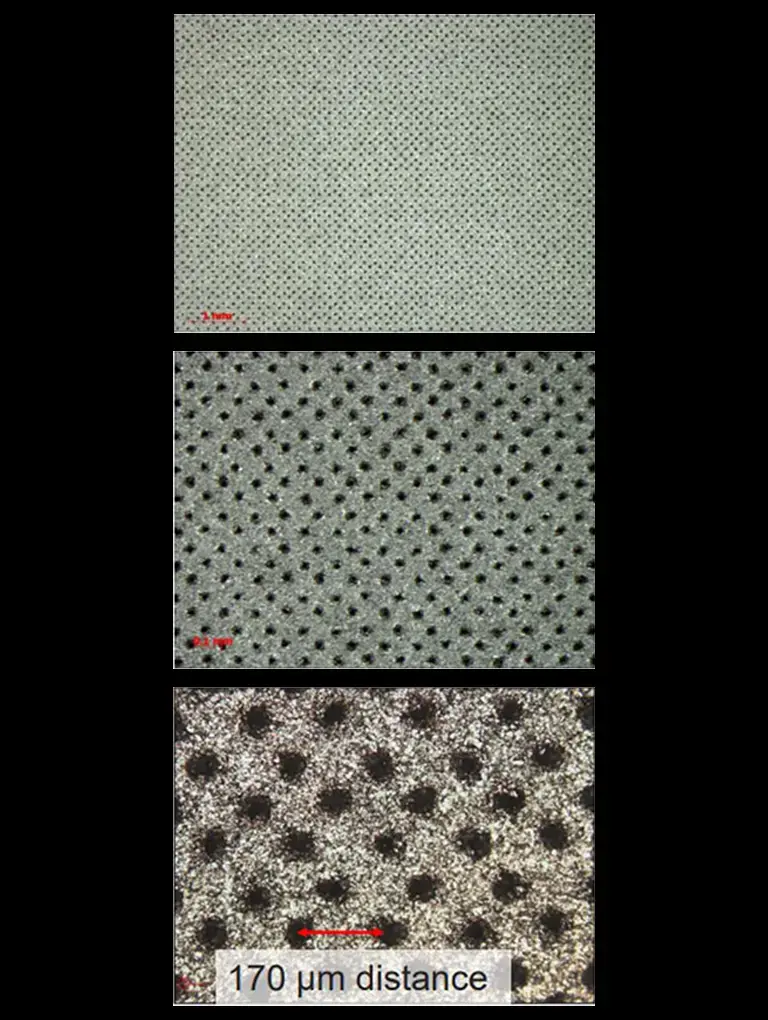

Drilling micro holes to reduce the tortuosity of the ion path through the porous electrode material. In effect speeding up the flow of ions by optimizing the pathways, enhancing battery efficiency.

Removing surface contaminants from battery tabs to ensure superior weld quality and electrical connectivity.

Enabling high-strength, low-resistance welds with minimal heat impact, improving battery safety and reliability.

Providing permanent, high-contrast traceability markings for quality assurance, compliance, and supply chain tracking.

Each of these applications contributes to higher energy density, improved cycle life, and streamlined manufacturing processes, reinforcing the importance of precision laser micromachining in next-generation battery production.

LASER SLITTING & CUTTING

HIGH-SPEED, BURR-FREE PROCESSING

FOR BATTERY FOILS

In battery manufacturing, precision slitting and cutting of battery foils - from mother to daughter coils - is critical for ensuring high-quality electrode production. Laser slitting & cutting provides a superior alternative to mechanical methods by delivering high-speed, non-contact processing with exceptional edge quality.

Key advantages include:

- Increased Throughput: Achieves processing speeds of over 2 meters per second, significantly improving production efficiency.

- Adjustable Coil Widths: Offers on-the-fly adjustments, enabling manufacturers to meet varying design specifications without mechanical retooling.

- Superior Edge Quality: Produces clean, burr-free cuts, eliminating defects that can impact battery performance.

- No Electrode Coating Smearing: Prevents contamination and material distortion, preserving the integrity of the active material.

- Eliminates Post-Processing: Requires no additional finishing steps, streamlining production and reducing operational costs.

- Optimised for Battery Materials: Typically utilises nanosecond pulsed lasers in the infrared (IR) wavelength, ensuring precise and controlled ablation.

With laser slitting and cutting, battery manufacturers achieve higher precision, reduced material waste, and enhanced production flexibility, reinforcing the role of laser micromachining in next-generation battery fabrication.

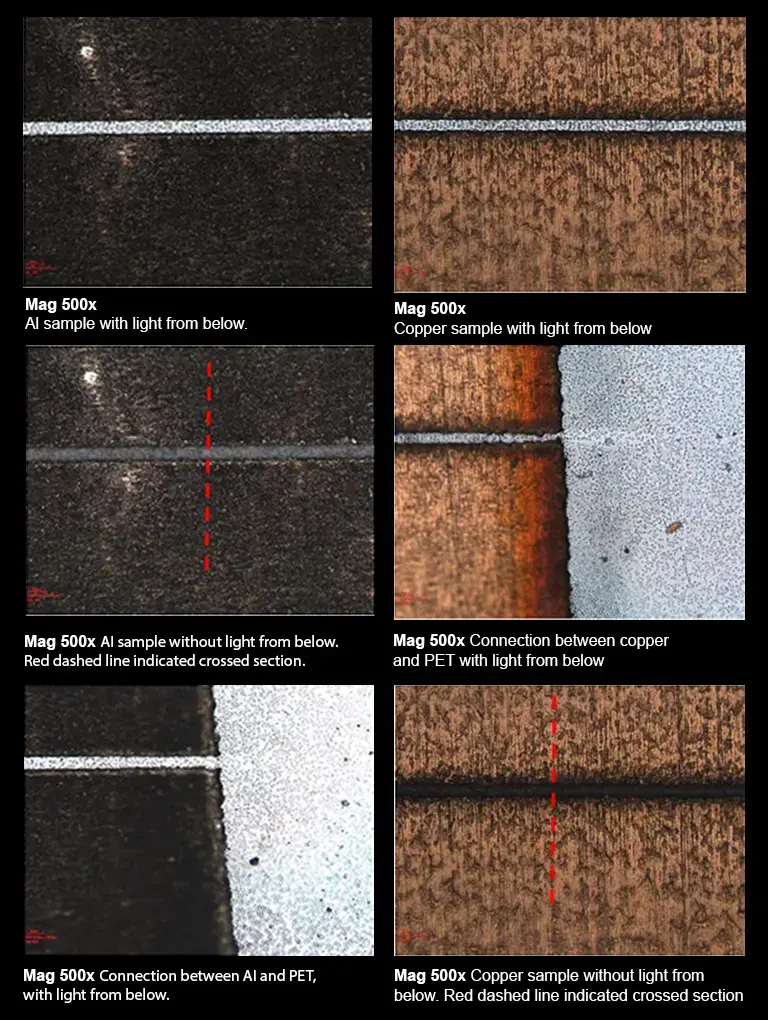

LASER FOIL CUTTING & ABLATION

HIGH-PRECISION PROCESSING FOR BATTERY FOILS

Battery foil cutting and ablation are critical steps in battery manufacturing, requiring high precision, minimal heat impact, and superior edge quality. Traditional cutting and stamping methods often introduce mechanical stress, burrs, and contamination, leading to compromised battery performance. Laser foil cutting and ablation provide a non-contact, high-speed solution that eliminates these issues while significantly increasing throughput.

Key benefits include:

- Superior Throughput: Processes battery foils at speeds far exceeding conventional cutting and stamping methods.

- Enhanced Edge Quality: Achieves burr-free cuts with no smearing, preserving the integrity of electrode materials.

- Minimal Heat-Affected Zone (HAZ): Keeps HAZ under 10μm, preventing material degradation and preserving electrochemical properties.

- No Post-Processing Required: Delivers clean, precise cuts without the need for additional finishing steps.

- Optimized for Speed: Operates with conveyor speeds of 0.5 meters per second and laser ablation speeds of 7 meters per second, maximising production efficiency.

- Advanced Laser Technology: Utilises picosecond lasers in the infrared (IR) and second harmonic generation (SHG) wavelengths, ensuring ultra-fast material removal with extreme precision.

By implementing laser foil cutting and ablation, battery manufacturers can achieve higher efficiency, reduced material waste, and superior component quality, reinforcing the role of laser micromachining in next-generation battery production.

LASER STRUCTURING

OPTIMIZING ELECTRODE SURFACES FOR FASTER CHARGING & LONGER BATTERY LIFE

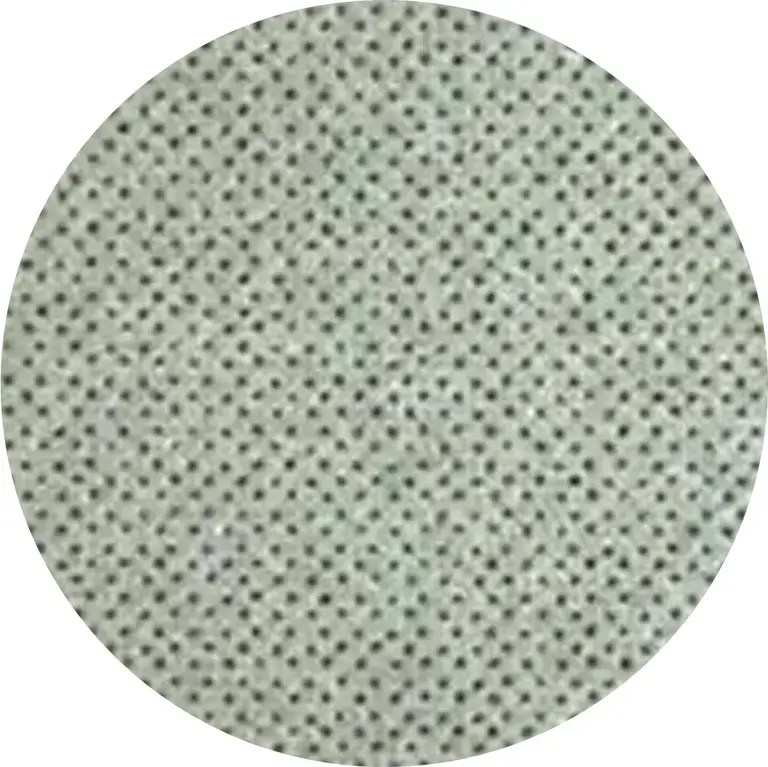

Laser structuring is a key innovation in battery manufacturing, enabling precise modification of electrode surfaces to enhance ion transport efficiency. By optimising pathways for ion movement, laser structuring significantly improves charge acceptance, leading to faster charging times and extended battery life.

Key advantages include:

- Enhanced Electrode Performance: Increases active surface area, improving electrochemical reaction efficiency.

- Optimised Ion Flow Pathways: Creates structured patterns that reduce resistance and accelerate ion transport.

- Faster Charging Times: Enables quicker charge cycles without compromising battery integrity.

- Longer Battery Life: Reduces electrode degradation, extending overall cycle life.

- Precision Processing: Utilises femtosecond lasers in the infrared (IR) wavelength, ensuring ultra-fast, high-precision structuring with minimal heat impact.

By integrating laser structuring, battery manufacturers can develop higher-performance energy storage solutions, addressing industry demands for greater efficiency, durability, and scalability in next-generation battery technologies.

LASER BATTERY TAB CLEANING

ENSURING RELIABLE WELDS

& HIGHER PRODUCTION YIELDS

Battery tab cleanliness is critical for ensuring strong, defect-free welds, particularly in ultrasonic and laser welding applications. Contaminants such as oxidation, dust, and residue can lead to weak welds, increased defect rates, and costly rework. Laser tab cleaning provides a precise, non-contact solution for removing surface impurities, optimizing welding performance, and improving overall battery reliability.

Key advantages include:

- Effective Contaminant Removal: Eliminates surface oxidation and contamination, ensuring optimal weld adhesion.

- Prevents Weld Failures: Significantly reduces defects, especially in ultrasonic welding, where clean surfaces are essential.

- Increased Production Yield: Enhances welding consistency and quality, minimizing scrap rates.

- Reduced Rework & Downtime: Lowers the need for secondary cleaning steps, improving manufacturing efficiency.

- Advanced Laser Technology: Typically utilizes nanosecond lasers in the infrared (IR) wavelength, ensuring high-speed, precise cleaning without damaging the material.

By integrating laser tab cleaning, manufacturers achieve higher process reliability, reduced failure rates, and improved production scalability, reinforcing its essential role in next-generation battery assembly.

LASER WELDING

HIGH-PRECISION, NON-CONTACT JOINING FOR BATTERY CASINGS & TABS

Laser welding is a critical process in battery manufacturing, providing a high-speed, highly controlled method for joining battery casings and tabs. Traditional welding techniques often introduce excessive heat, deformation, and material inconsistencies, leading to defects that compromise battery performance and safety. Laser welding, however, offers a non-contact, precise, and efficient alternative that ensures strong, reliable joints with minimal thermal impact.

Key advantages include:

- Non-Contact Processing: Eliminates mechanical stress and tool wear, enhancing weld consistency.

- Access to Restricted Areas: Enables welding in tight or complex geometries, making it ideal for compact battery designs.

- High-Speed, Low-Deformation Welding: Delivers strong, clean welds with minimal material distortion, ensuring structural integrity.

- Precise Control Over Weld Size & Location: Achieves micron-level accuracy, optimizing electrical conductivity and mechanical strength.

- No Post-Processing or Cleaning Required: Produces clean, defect-free welds, eliminating the need for secondary finishing steps.

- Versatile for Dissimilar Materials: Supports joining of different materials, including aluminium, copper, and nickel, essential for advanced battery designs.

- Optimised Laser Technology: Typically employs millisecond lasers in the infrared (IR) or second harmonic generation (SHG) wavelengths, ensuring deep penetration and strong metallurgical bonding.

By adopting laser welding, battery manufacturers benefit from higher production efficiency, superior weld quality, and greater design flexibility, reinforcing its role in next-generation battery assembly.

LASER MARKING

HIGH-SPEED, PERMANENT IDENTIFICATION FOR BATTERY CASINGS

In battery manufacturing, traceability and product identification are essential for quality control, compliance, and supply chain management. Laser marking provides a non-contact, high-speed solution for applying permanent markings—such as serial numbers, 2D data codes, and alphanumeric text—directly onto battery casings without the need for inks or consumables.

Key advantages include:

- Non-Contact Process: Ensures precise, damage-free marking without mechanical wear.

- High-Speed Marking: Enables rapid processing, optimizing high-volume production lines.

- Permanent, Ink-Free Marking: Provides durable, tamper-proof identification for lifetime traceability.

- Versatile Marking Capabilities: Supports serial numbers, alphanumeric text, logos, and 2D barcodes for comprehensive tracking.

- Micro-Precision Marking: Achieves feature sizes as small as <20μm, ensuring legibility without affecting battery integrity.

- On-the-Fly Marking: Allows real-time marking during production without requiring line stoppages.

- Advanced Laser Technology: Typically employs nanosecond lasers in the infrared (IR) wavelength, ensuring high contrast and long-lasting results.

With laser marking, battery manufacturers achieve seamless traceability, improved brand protection, and streamlined production efficiency, making it a crucial step in modern battery manufacturing.

LASER MICROMACHINING

THE FUTURE OF BATTERY MANUFACTURING

In the late 1960s and early 1970s, lasers were often seen as a solution looking for a problem. Today, they are a cornerstone of advanced manufacturing, particularly in the battery industry, where precision, efficiency, and sustainability are paramount.

Laser technology offers unmatched advantages in battery production, including:

- Precision & Control – Enables intricate microstructures that enhance battery performance.

- Efficiency – Processes like laser drying can reduce energy consumption by up to 50%, making manufacturing more cost-effective.

- Improved Battery Performance – Laser structuring optimizes ion transport, leading to faster charging times and longer cycle life.

- Environmental Benefits – Lower material waste and the elimination of consumables support sustainable manufacturing.

- Speed & Scalability – High-speed, automated laser processing enables mass production for EV and energy storage markets.

With these benefits, laser technology is accelerating the evolution of battery manufacturing, ensuring scalability, reliability, and cost-efficiency.

OPTEK SYSTEMS

YOUR BATTERY PRODUCTION PARTNER

With the battery industry rapidly evolving, precision laser micromachining is enabling manufacturers to meet growing market demands, enhance efficiency, and improve product reliability. By integrating advanced quality assurance, machine learning, and scalable processing, OpTek Systems delivers next-generation battery manufacturing solutions.

OpTek Systems has over 20 years of expertise in laser micromachining, providing:

- 50-Micron Demetalised Tracks – Essential for high-energy-density battery configurations.

- Edge Definition <2 Microns – Eliminating inconsistencies that lead to battery defects.

- No Impact on Electrical Performance – Maintaining electrode conductivity after processing.

- Multi-Track & Reel-to-Reel Processing – Supporting high-volume production with minimal downtime.

With proven success in processing millions of components per month, OpTek ensures cost-effective, repeatable, and scalable solutions for next-generation battery manufacturing.

Ready to revolutionise your battery manufacturing? Contact OpTek Systems today for scalable, high-precision laser solutions that improve efficiency, performance, and cost-effectiveness.