Precision Modified Surfaces

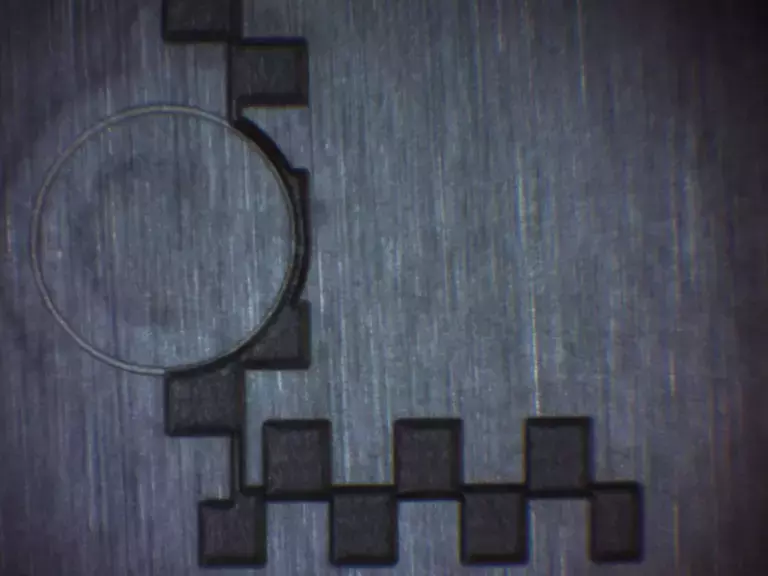

Through the careful application of the correct laser type and the appropriate processing parameters and conditions, our highly experienced engineers are able to create precisely modified surfaces. The range of possibilities is significant, but these include roughening to assist with the retention of lubrication on a material surface, to the creation of electrically conducting and insulating regions on the surface of a substrate. It is possible to increase or decrease porosity in some materials, and we can create 2D and 3D structures on flat and shaped materials.

Contact us to discuss your specific application.

Specifications

Key Features

• Range of lasers address any material type or combination

• Flexibility to define feature size, shape, type, and period

• Selectively machine individual layers from stacks and laminates

• Processing of flat and 3D materials

• Ability to control thermal inputs and gradients, to remove, reflow or alloy materials

• Range of advanced processing techniques