At OpTek Systems, we harness the power of precision laser processing to drive advancements in biomedical applications.

Our expertise spans a wide array of critical procedures and technological innovations, ensuring that medical professionals have the tools they need to provide top-tier patient care. From endodontic procedures to advanced diagnostic techniques, our solutions are at the forefront of medical technology.

DIVERSE APPLICATIONS IN BIOMEDICAL TECHNOLOGY

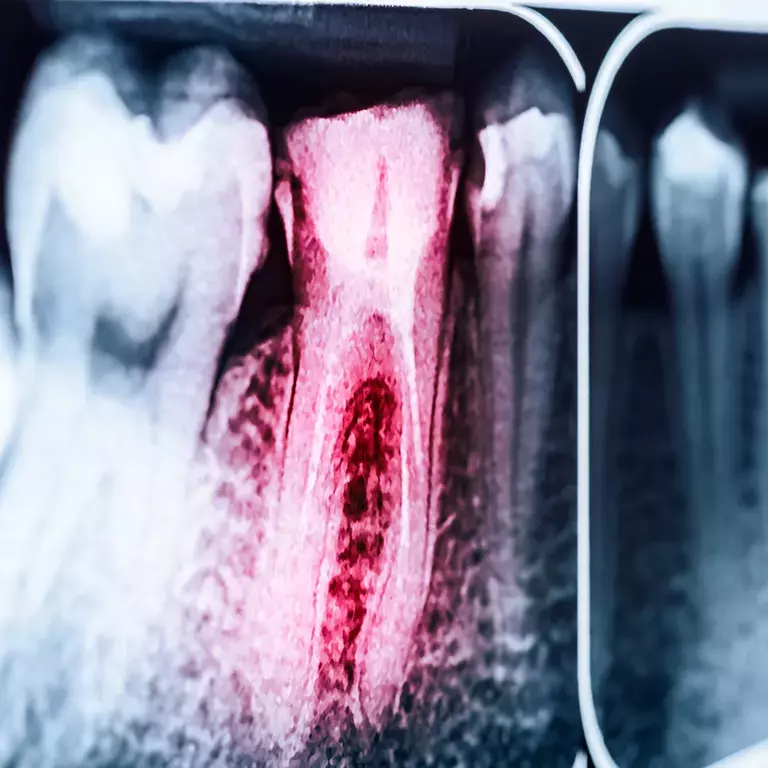

Specialized optical fiber tips and devices are frequently used in oral and endodontic procedures. Laser lensing capabilities enable the precise creation of fiber tips with intricate geometries suited for dental applications, such as radial light emission for minimally invasive procedures. Techniques like laser cleaving form flat, angled, or multi-faceted end faces on optical fibers, optimizing light transmission for intraoral light delivery. Laser stripping removes coatings like polyamide from optical fibers, ensuring biocompatibility for applications such as plaque ablation and gum reshaping. Directly machining lens geometries onto fiber tips via laser lensing further customizes beam profiles and focal lengths for dental procedures.

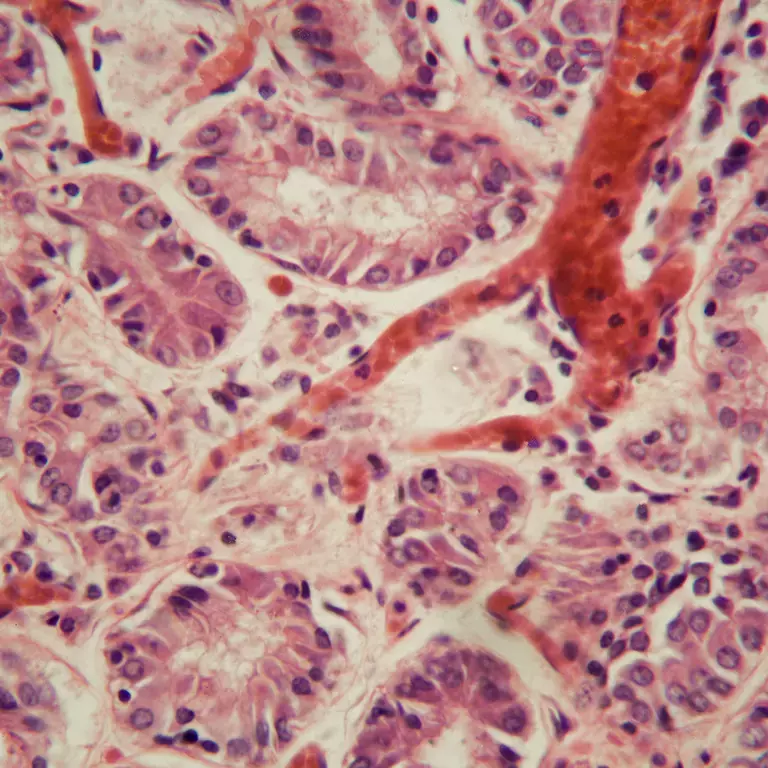

OpTek Systems advanced laser micromachining and optical fiber processing capabilities advance the production of tools crucial for endovenous laser ablation (EVLA) and reducing pulmonary embolism (PE) risk.

Our laser cleaving and lensing capabilities create precise end faces and intricate lens geometries on optical fibers, optimizing light delivery and beam profiles for effective vein ablation. Laser stripping and end capping processes are fully biocompatible and enhance EVLA fiber performance and reliability. We manufacture specialized fiber assemblies for EVLA, with radial emission of laser energy and side-firing fiber tips for targeted light delivery, minimizing PE risk. Robust quality control measures, including hermetic sealing and packaging, ensure the integrity and sterility of EVLA fiber assemblies, reducing contamination and defect risks. Our scalable production capabilities enable consistent and reliable high-quality EVLA fiber production.

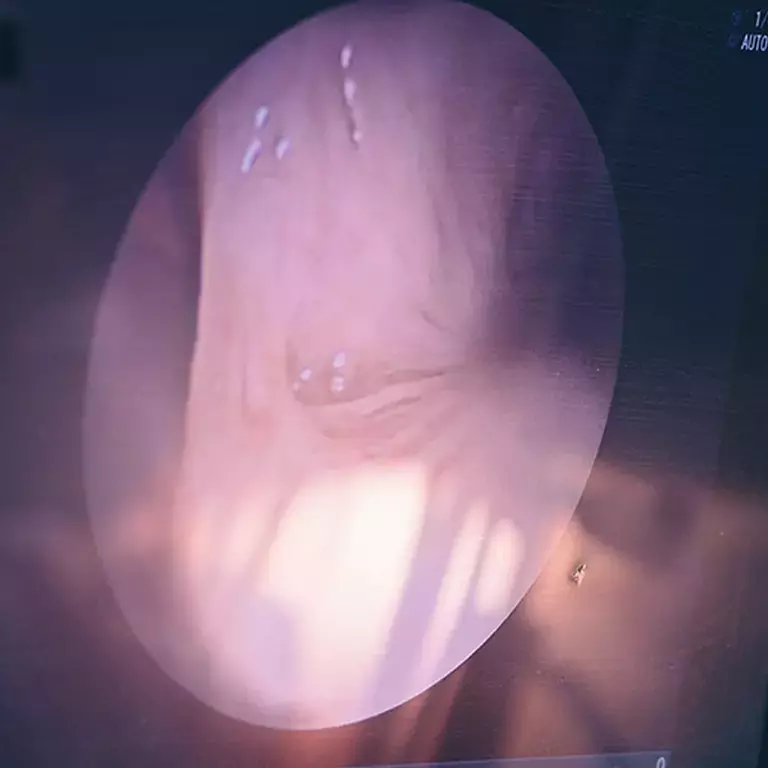

OpTek enables precise and safe endoscopic procedures and peripherally inserted central catheter (PICC) positioning. Our expertise in laser micromachining and optical fiber processing creates specialized endoscopic instruments and catheter positioning systems. Laser cleaving technology forms precise flat, angled, or multi-faceted end faces on optical fibers used in endoscopes, optimizing light transmission and imaging quality. Laser lensing capabilities allow direct machining of intricate lens geometries onto fiber tips, customizing beam profiles and focal lengths for specific endoscopic applications and enables radial or side-firing fiber tips for targeted light delivery and accurate catheter tip positioning during PICC placement Additionally, our laser stripping and end capping processes are fully biocompatible and ensure optimal performance of optical fibers within the body Hermetic sealing and packaging techniques maintain the integrity and sterility of these fiber assemblies, reducing complication risks. Scalable production capabilities facilitate consistent and reliable manufacturing of high-quality endoscopic and catheter positioning devices.

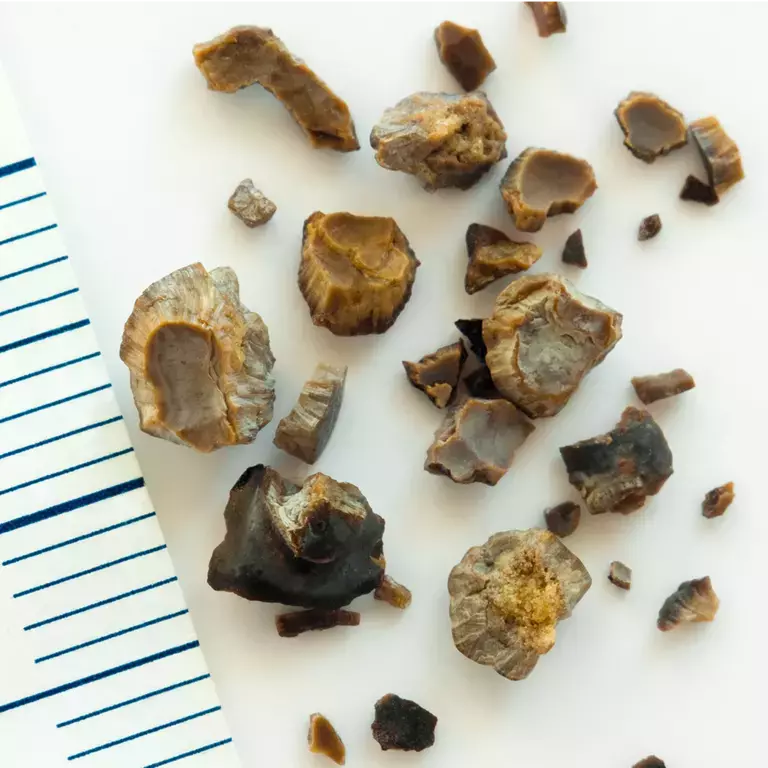

OpTek Systems leads in enabling precise and safe laser lithotripsy procedures through laser micromachining and optical fiber processing. Laser cleaving and lensing capabilities create specialized optical fibers with intricate geometries for lithotripsy, forming precise flat, angled, or multi-faceted end faces to optimize light transmission and energy delivery for effective stone fragmentation. Laser stripping and end capping processes ensure biocompatibility and enhance lithotripsy fiber performance within the urinary tract. Hermetic sealing techniques ensure the integrity and sterility \ fiber assemblies used in lithotripsy procedures,

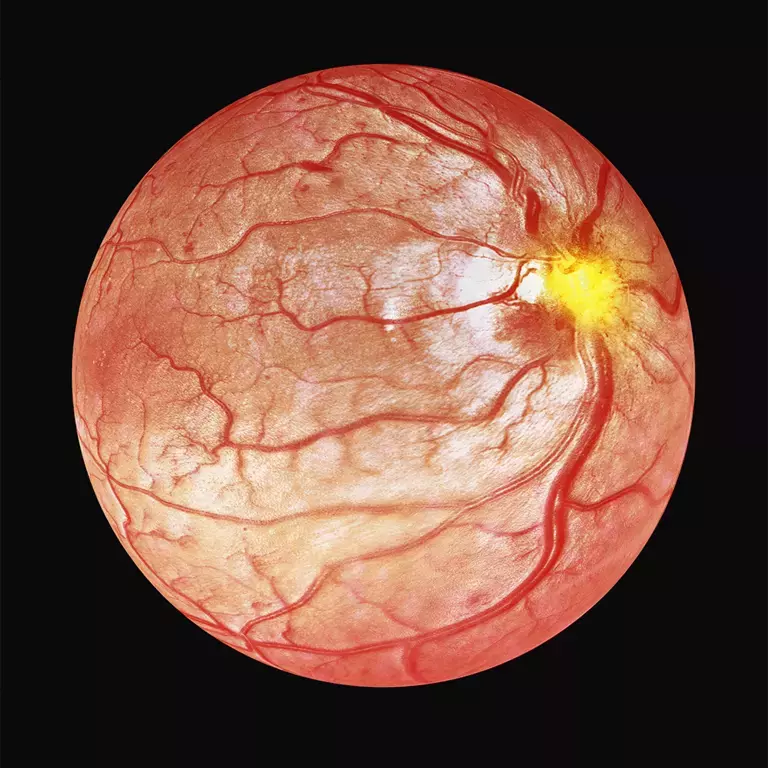

OpTek Systems advances optical coherence tomography (OCT) imaging systems with laser micromachining and optical fiber processing. Laser cleaving technology creates precise flat, angled, or multi-faceted end faces on optical fibers used in OCT probes, optimizing end face geometry for efficient light transmission and high-quality OCT images. Laser lensing capabilities allow direct machining of intricate lens geometries onto OCT fiber tips, customizing beam profiles and focal lengths for specific applications like retinal imaging, coronary interventions, or material characterization. Laser stripping and end capping processes are fully biocompatible and ensure optimal optical properties within the body, enhancing OCT probe performance and reliability. OpTek offers capital equipment and contract manufacturing services for OCT fiber processing and assembly, ensuring scalability and consistency in the medical imaging field.

COMPREHENSIVE FIBER PROCESSING CAPABILITIES

At OpTek, we understand the importance of scalability and reliability in the biomedical industry. That's why we offer both capital equipment and in-house contract manufacturing services for optical fiber processing. Our production line machine tools, ranging from desktop tools to fully automated systems, enable seamless integration of our processes into your manufacturing workflows. Alternatively, our subcontract services provide turnkey solutions, including fiber assemblies, terminators, connectors, feed-throughs and fiber Bragg gratings. Talk to us about testing our assemblies and probes in your harsh-environment.

BIOMEDICALFIBER PROCESSING CAPABILITIES

Precise cutting and shaping of optical fibers to meet specific application requirements, ensuring optimal performance in medical devices.

High-quality end caps for fiber assemblies, enhancing durability and functionality.

Efficient removal of protective coatings from fibers without damaging the underlying material, crucial for in-body applications.

Comprehensive solutions for assembling fiber optic components, ensuring precision and reliability.

Ensuring secure packaging including hermetic sealing for sensitive components.

COMMITMENT TO EXCELLENCE

Whether you require in-face geometry shaping, end capping, stripping, or hermetic sealing, OpTek's expertise ensures precision and quality at every step. Our commitment to innovation, coupled with our deep understanding of biomedical applications, makes us the ideal partner for bringing your cutting-edge ideas to reality.

Explore the possibilities of laser fiber processing for your biomedical applications. Contact our experts today to discuss your specific requirements and unlock the full potential of OpTek's advanced technologies.