Laser cleaving is a precision process for cutting and finishing optical fibers and connectors using a laser. Unlike traditional mechanical methods, laser cleaving delivers unmatched quality, repeatability and scalability, critical for today’s high-performance fiber optic applications.

OpTek Systems has been pioneering laser processing technologies that cleave, lens, and strip optical fiber since the 1990s, supporting industries from telecom and datacom to semiconductors, biomedical and aerospace. Our LaserCleave™ product range and in-house cleaving services offer reliable, high-volume fiber termination solutions that save time, reduce costs and maximize yield.

What is Laser Cleaving?

Laser cleaving cuts the optical fiber in a highly controlled and repeatable manner.

The result is an optical-grade surface with:

- Smooth, flat end faces suitable for immediate use in many connectorization processes.

- Consistent cleave lengths and angles, even on complex connector formats such as multi-fiber arrays.

- Reproducible performance, enabling high yield in both R&D and large-scale manufacturing environments.

Laser cleaving is particularly valuable because it can be configured for a wide range of applications, from single-fiber terminations to ribbon cleaves and advanced interconnect technologies such as MXC and LightTurn® connectors.

How Does Laser Cleaving Work?

- Fiber Alignment: The optical fiber or connector is precisely positioned within the cleaving tool using appropriate tooling.

Laser Application: The fiber is exposed to the laser.

- Finished Cleave: The result is a smooth, optical-quality end face that often requires little or no post-processing.

In short, laser cleaving provides the accuracy and repeatability that modern fiber optic production demands, while laying the foundation for scalable, automated manufacturing solutions.

Laser cleaved optical fiber at 10 degrees

Laser cleaved optical fiber at 45 degrees

Laser cleaved optical fiber with a tapered cleave

LASER CLEAVING VS. TRADITIONAL METHODS

Traditional fiber cleaving relies on mechanical scribing and breaking, which can leave imperfections such as cracks, chipping, and epoxy residues. These irregularities increase polishing requirements, reduce yield, and compromise performance. Mechanical processes are also operator-dependent, leading to inconsistent results.

By contrast, laser cleaving uses a non-contact, automated laser process that:

- Cuts fiber cleanly and precisely often relative to a connector edge.

- Eliminates core cracks, chipping, and hackle.

- Minimizes or even removes the need for polishing on connectors

- Improves first-pass yield and throughput while reducing consumables and hazardous waste.

Independent performance comparisons show that laser cleaved fibers deliver >4 dB better return loss than polished fibers and are nine times more reproducible than mechanical cleaves. This means higher performance, lower cost, and more reliable production.

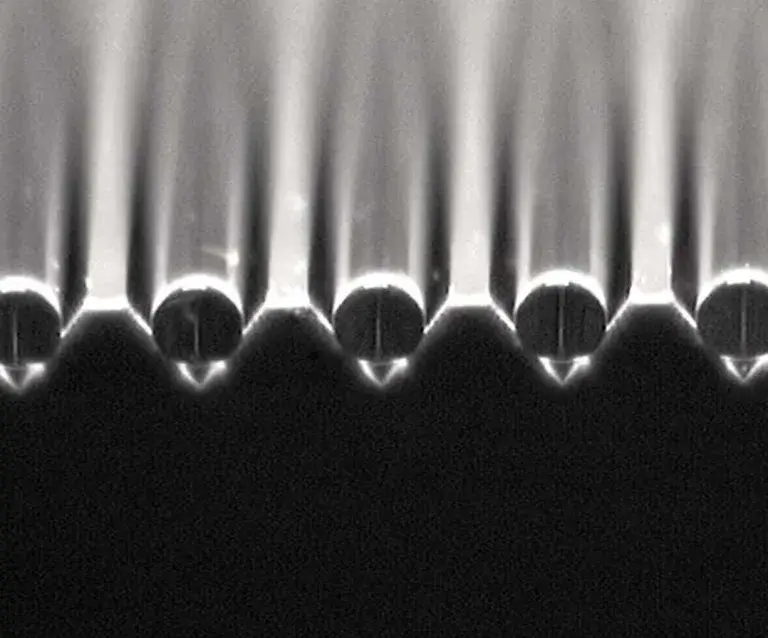

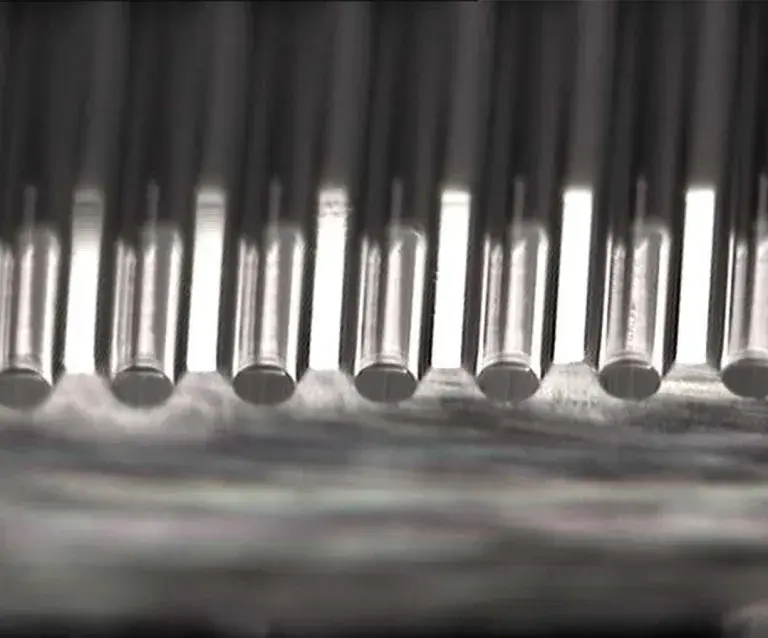

Laser Cleaved Optical Fiber with Coating (top)

Laser Cleaved Optical Fiber with Coating (side)

Applications of Laser Cleaving

Laser cleaving plays a pivotal role across diverse sectors requiring high-performance optical fiber termination. By delivering precise, reliable cleaves with exceptional reproducibility, it has become a cornerstone technology in several major industries:

Laser cleaving ensures rapid, repeatable preparation of connectors like LC, SC, MT, MXC, and LightTurn® . Essential for high-density networks and hyperscale data centers, it supports superior return loss and cost efficiency, making it ideal for optical fiber assemblies used in this sector.

In photonic integrated circuits and advanced packaging, laser cleaving offers pinpoint control over cleave length and angle, enhancing coupling efficiency in high-precision applications.

Critical in the preparation of fiber assemblies for medical diagnostics and therapeutic equipment, laser cleaving supports tailored geometries (e.g., short tails, angled cleaves) while maintaining signal fidelity under demanding conditions.

Aerospace-grade systems require durability and precision under extreme conditions. Laser cleaving provides consistent, low-defect terminations in sensing and communication applications vital for avionics and onboard fiber systems.

In defense environments, where robust communication and sensing are mission-critical, laser cleaving enables the creation of reliable, high-performance fiber terminations for systems including optics, propulsion, and secure networks.

For standards under development, like Thunderbolt, optical USB, or Active Optical Cables, laser cleaving enables fast, scalable fiber processing to support high-volume consumer production.

Fiber Array Units (FAUs)

Fiber Array Units are essential in datacom, silicon photonics and optical device packaging, where multiple fibers must be precisely aligned to components such as photonic integrated circuits (PICs).

Laser cleaving enables FAU production by:

- Delivering uniform cleave lengths across entire fiber arrays, ensuring consistent termination.

- Supporting angled cleaves for low-reflection interfaces in high-speed datacom.

- Achieving fiber-to-fiber consistency with tolerances as tight as ±2 μm.

- Reducing polishing steps, saving time and minimizing variability in array assembly.

- Enabling efficient stress rod orientation for polarization maintaining fibers.

This precision makes FAUs produced with laser cleaving ideal for hyperscale data centers, telecom networks, and next-generation photonics platforms.

Hermetic Fiber Assemblies

Hermetic assemblies protect optical fibers in harsh environments such as aerospace, defense, and biomedical devices, where systems must withstand temperature extremes, moisture and pressure.

Laser cleaving supports hermetic assembly manufacturing by:

- Producing optical-grade cleaves close to the sealing point for compact, high-reliability designs.

- Ensuring clean end faces for fibers before sealing into glass, ceramic, or metal housings.

- Supporting specialty fibers (e.g., polarization-maintaining) where precise geometry is critical.

- Enabling high-yield, reproducible production of assemblies for satellite communications, avionics, and medical sensing systems

End Capping for High-Power Devices

End capping requires splicing or fusing “coreless” fiber to single-mode (SM) fiber or mutimode (MM) fiber transmitting/gain fiber in an attempt to reduce power densities (J/cm2), thus increasing the damage threshold of the component. Laser cleaving is an integral part of the end capping process, offering:

- Flat surfaces of both large and small-diameter fibers that are free of hackle and chips.

- Precise length control (within microns) of the end cap.

- A polish-free processing option for improved power handling.

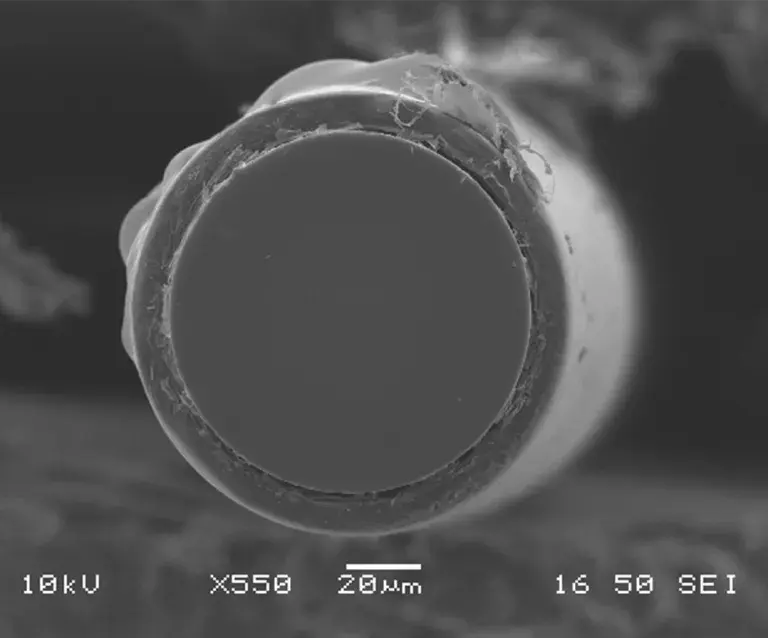

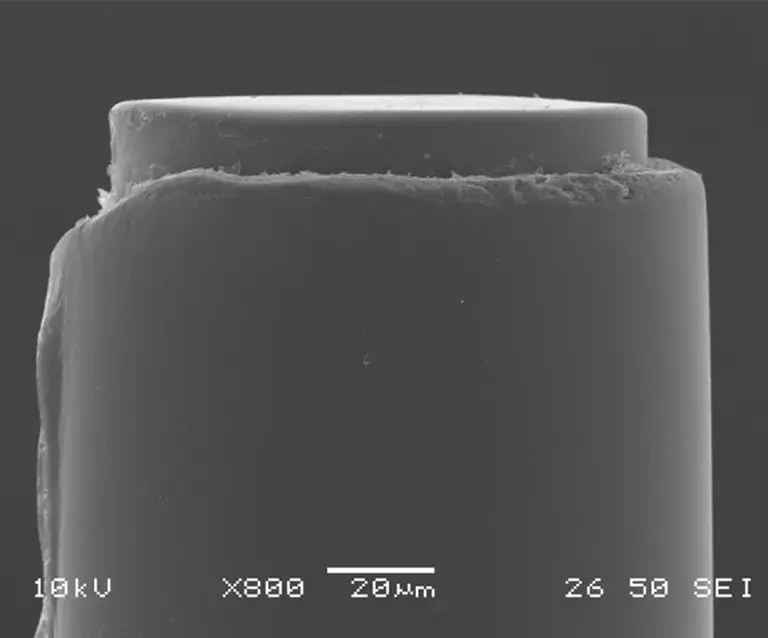

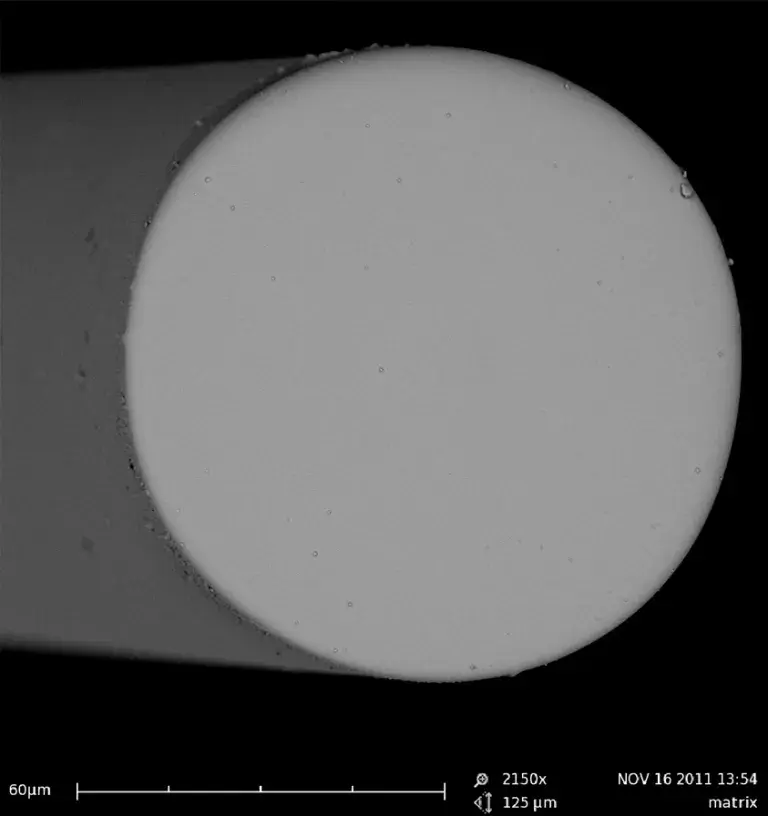

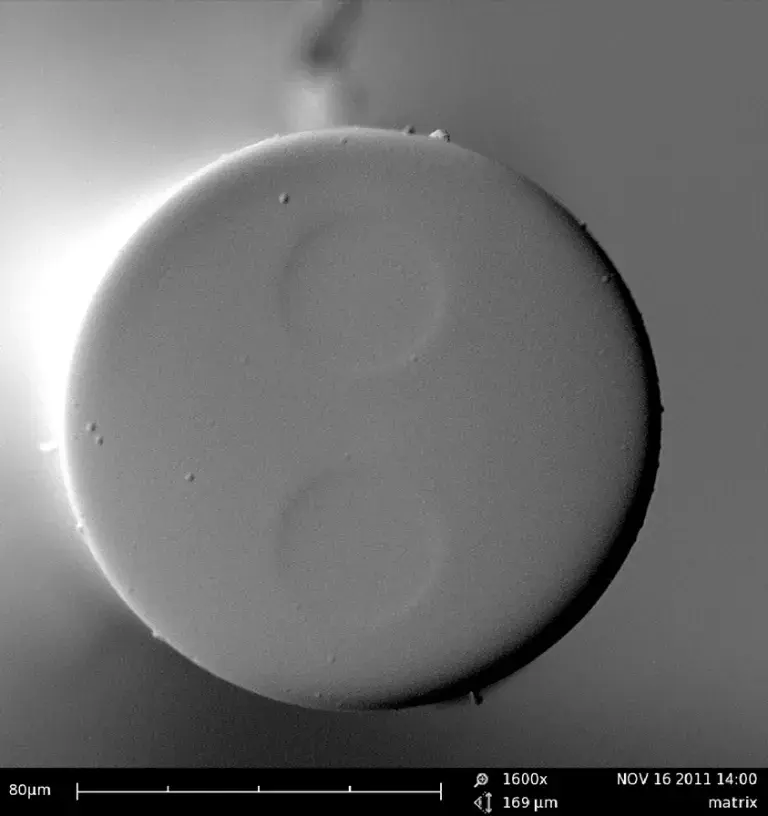

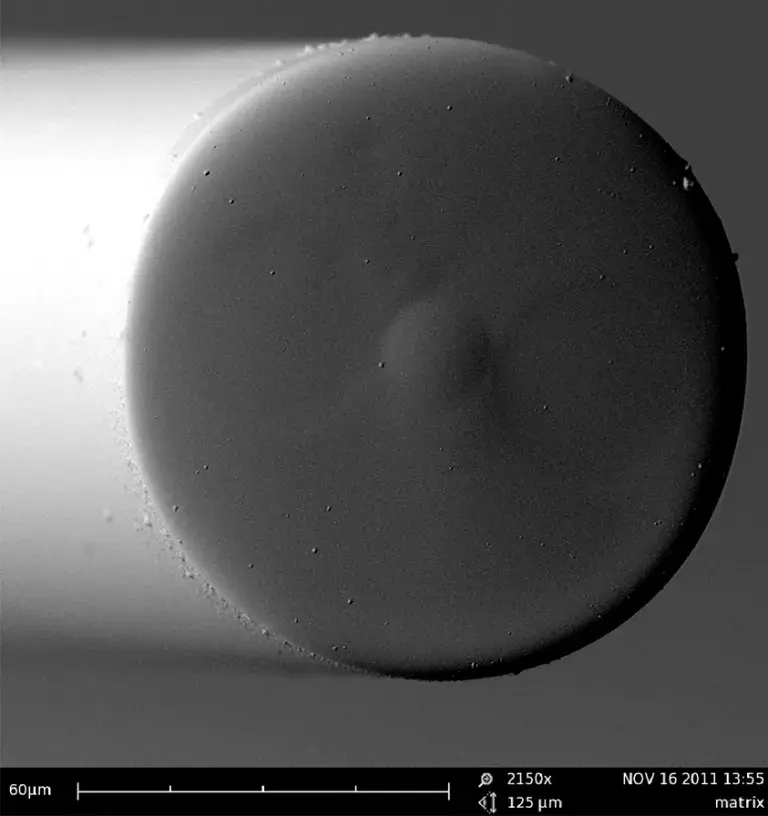

Single Mode (SM) Fiber Laser Cleave End Quality

Polarizing Maintaining (PM) Fiber Laser Cleave End Quality

Multi Mode (MM) Fiber Laser Cleave End Quality

OPTEK SYSTEMS: YOUR LASER CLEAVING PARTNER

Founded in 2000, OpTek Systems is a global leader in laser micromachining and fiber processing solutions. With operations in the UK, USA, and Asia, we provide both turnkey production equipment and subcontract manufacturing services.

We have partnered with leading technology companies worldwide, supplying LaserCleave™ systems that are validated for emerging interconnect standards such as MXC, LightTurn®, Thunderbolt, and optical USB. Our solutions are trusted in applications ranging from pump laser diodes to active optical cables.

At the heart of our offering is a commitment to automation, consistency and scalability, helping customers transition from R&D to full-scale production with confidence.

OPTEK’S LASERCLEAVE™ PRODUCT RANGE

The LaserCleave™ series has been refined over decades to meet the needs of fiber optic manufacturers worldwide. Each model addresses different production volumes and connector formats:

A compact, tabletop platform designed for connector manufacture. It reduces cost, improves yield, and eliminates polishing steps. Ideal for 1.25mm, 2.5mm, and MT connectors.

A versatile, high-throughput cleaving system with interchangeable fixtures for multiple connector types, including PRIZM® MT and MXC. Provides control over fiber end geometry for consistent, optical-grade results.

A fully automated, cassette-fed cleaving system engineered for high-volume manufacturing of optical-grade fiber connectors. It offers operator-independent performance, exceptional reproducibility, and turnkey integration.

Each LaserCleave™ machine is designed for rapid, non-contact processing with minimal consumables, giving customers scalable solutions for today’s and tomorrow’s fiber optic demands.

Watch our demostration video below to see the LaserCleave™ 1000 in action.

OUR IN-HOUSE LASER CLEAVING SERVICES

At OpTek, we understand that not every manufacturer is ready to install dedicated equipment. That’s why we offer precision laser cleaving as a subcontract service, giving you the flexibility to outsource your fiber processing when it makes the most sense for your business.

Our cleaving services allow you to take advantage of the same LaserCleave™ technology trusted by global manufacturers, without the capital investment. Whether you need low-volume prototype batches or high-volume production support, OpTek delivers:

- Optical-grade cleaves with exceptional accuracy and reproducibility.

- Rapid turnaround times to keep your projects moving.

- Scalable solutions — outsource today, invest in your own LaserCleave™ system tomorrow.

- Flexibility across applications, from connector termination to advanced assemblies.

By choosing OpTek’s in-house services, you gain the assurance of proven process control and global support from our facilities in Europe, North America, and Asia. This makes our subcontract services the ideal bridge between R&D, pilot production, and full-scale manufacturing.

Get in Touch

Whether you’re looking to outsource fiber cleaving or invest in a dedicated LaserCleave™ system, OpTek Systems is here to help. Our team of experts will work with you to find the right solution, balancing performance, cost, and scalability for your application.

Contact our sales team today to discuss your requirements and discover how OpTek’s laser cleaving solutions can transform your fiber processing.